Tim@TBDevelopments

Lifer

In recent years i have started doing my own fabrication inhouse. Here are a few example of it. Please forgive not all of it is Starlet but gives you some ideas of what i do.

Custom Intercooler Piping on an Unclocked Turbocharger

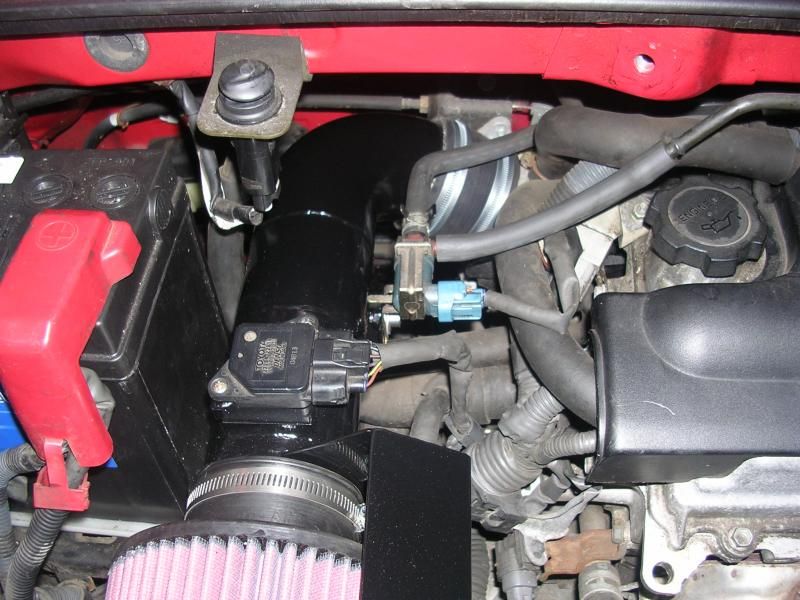

Same Car but Custom Straight Intake

Again Same car but Custom Turbocharger Headshield

A Custom 3" B Pipe

Custom 4" Intake System for an Mr2, but GT4 versions can also be easily made, This is in a raw state before any polishing or powdercoating

A simple Intake system Made For an Non-Turbo Mr2

Again a Custom Intake and IC Pipping for an Mr2 Build i Did, Recirc Setup on the BOV

Same Car As Above, The Customer Asked Me To Do A More Professional Job Of Running The Chargecooler Water Pipe Work Which Before Were Just Lay All Over The Top Of The Engine Bay, This Is What I Came Up With, When The Engine Is In You Can't Even See The Pipe Work

Another Example Of Some Custom Intercooler Pipe Work

A Custom Methanol Tank Made For A Toyota Glanza To Mount to Factory Rear Brace

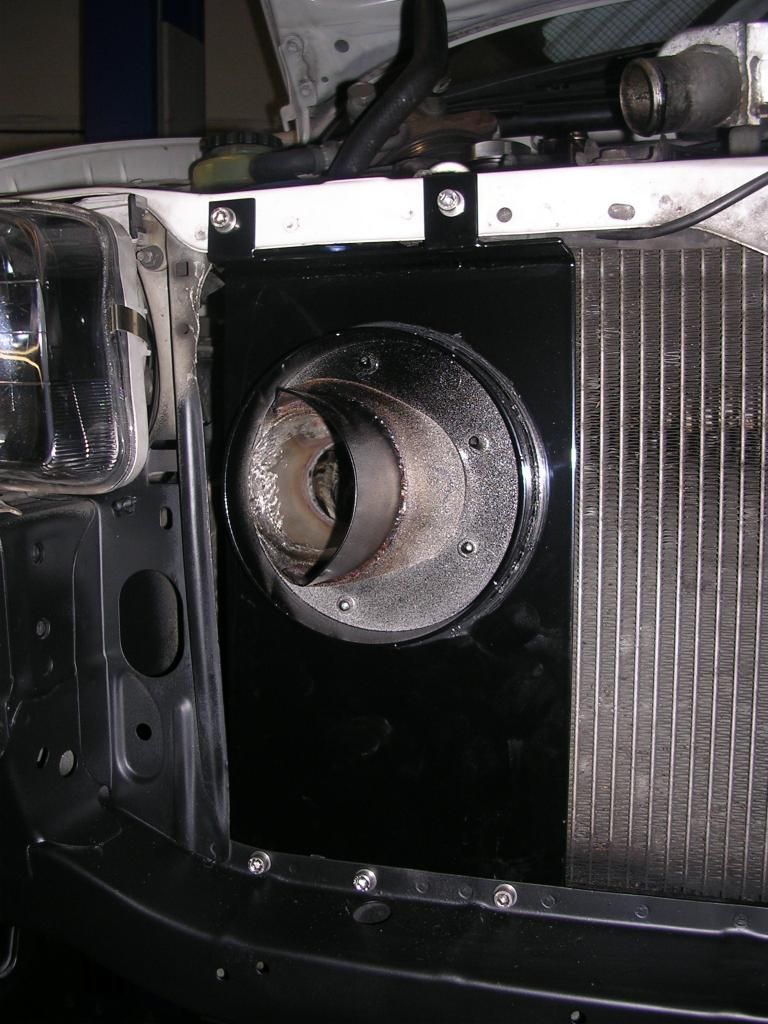

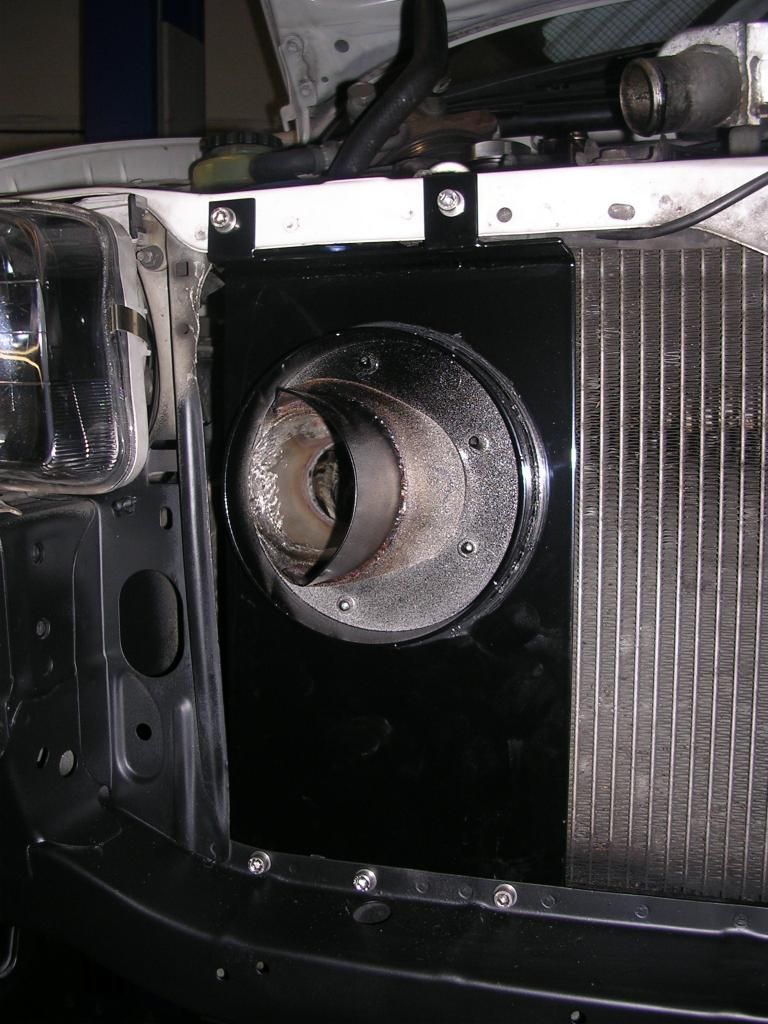

A Straight Intake Filter for Front Bumper Mount On A Toyota Glanza, Removes 13ft of Intake Pipework

A Custom Designed Intercooler That Didn't Require Cutting Of The Front Bumper

I Have Also Done Fibreglass And MDF Fabrication In The Case Of This Nitrous Bottle Holder to Replace The Centre Concole On and Mr2, This was taken prior to the rear being carpeted and the front wrapped in matching vyanl to the standard interior

Custom Intercooler Piping on an Unclocked Turbocharger

Same Car but Custom Straight Intake

Again Same car but Custom Turbocharger Headshield

A Custom 3" B Pipe

Custom 4" Intake System for an Mr2, but GT4 versions can also be easily made, This is in a raw state before any polishing or powdercoating

A simple Intake system Made For an Non-Turbo Mr2

Again a Custom Intake and IC Pipping for an Mr2 Build i Did, Recirc Setup on the BOV

Same Car As Above, The Customer Asked Me To Do A More Professional Job Of Running The Chargecooler Water Pipe Work Which Before Were Just Lay All Over The Top Of The Engine Bay, This Is What I Came Up With, When The Engine Is In You Can't Even See The Pipe Work

Another Example Of Some Custom Intercooler Pipe Work

A Custom Methanol Tank Made For A Toyota Glanza To Mount to Factory Rear Brace

A Straight Intake Filter for Front Bumper Mount On A Toyota Glanza, Removes 13ft of Intake Pipework

A Custom Designed Intercooler That Didn't Require Cutting Of The Front Bumper

I Have Also Done Fibreglass And MDF Fabrication In The Case Of This Nitrous Bottle Holder to Replace The Centre Concole On and Mr2, This was taken prior to the rear being carpeted and the front wrapped in matching vyanl to the standard interior