Tim@TBDevelopments

Lifer

few pictures from a build I'm doing for Nik.

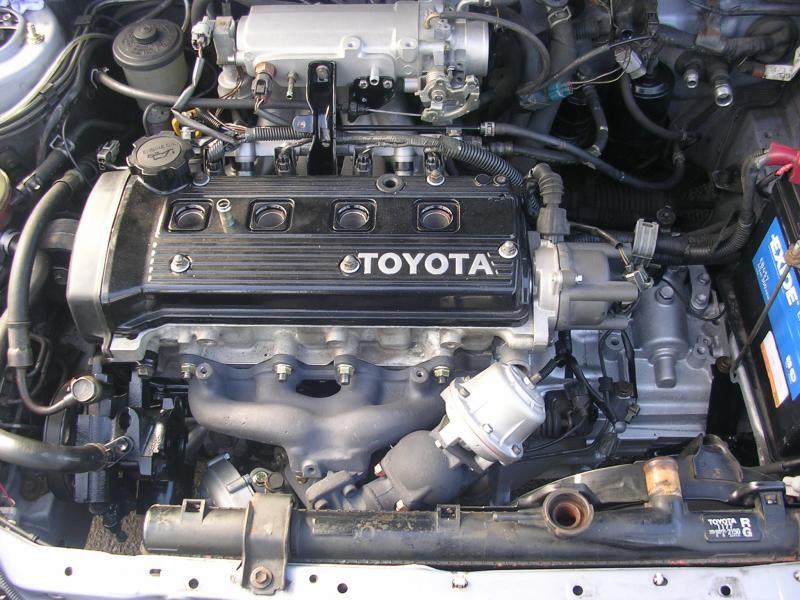

The engine arrived in the car in a bit of a sorry state, the engine had a rattle, it smoked and there was debit in the sump. Upon strip down I found that the rattle was caused by the previous company that rebuilt his head hadn't tensioned the camshaft cogs. The smoking was down to a very poorly turbocharger. And if it hadn't had been for this other issue the engine was actually perfect. BUT, unfortunately while the car was off the road because of these faults Nik had been carrying out some modifications, FMIC, Intake and bought a nicely powder-coated black rocker cover. Well the person he purchased it from had shot-blasted it and not told Nik. So upon fitting and running all the shot stuck under the baffles in rocker cover worked themselves loose, got into the oil system and destroy the engine.

Unfortunately the block and some parts of the head were totally destroyed and un-usable. The crank had been worn so badly it was beyond even repair by regrinding, the bores were badly scored to much for a re-bore, And the head and cams suffered light scoring that thankfully was fixable.

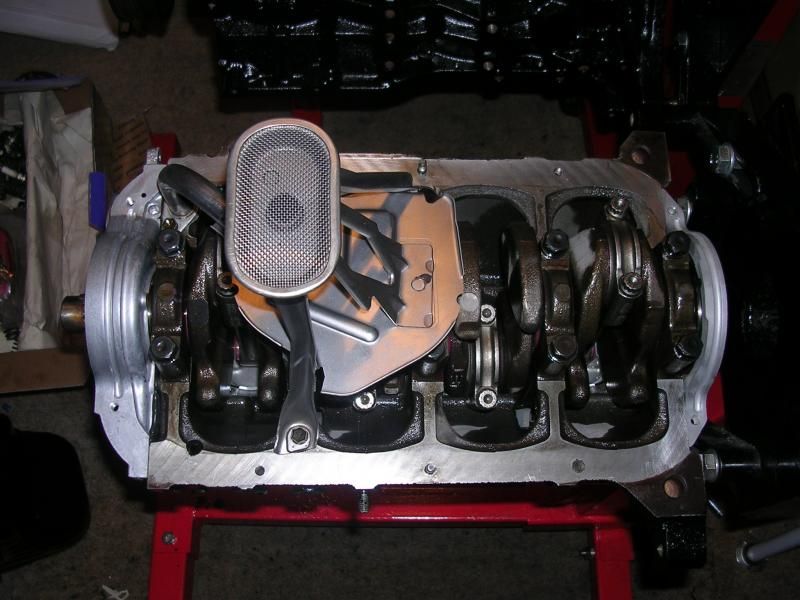

The engine was completely rebuild built from the ground up. Using my own design Wiseco Forged Pistons, Scat Conrods, ARPs, Metal Headgasket, ACL Bearings. The block was first ultrasonic tested for thickness and locally ex-rayed for internal crack structure. bored and honed using my own torque plate, to simulate head stresses and coolant at 82 degrees passed around the block to simulate block expansion under temperature. This ensures all the cylinders are all perfectly round not when sat on a stand but when under operation and running in the car. Pistons are measured and cylinders bored to that cylinder seeing all pistons are very slightly different sized. So #1 piston now goes into #1 cylinder. Again this maintains perfect piston to cylinder clearances. All static and rotationally parts balanced to 1/3rd of a gram which is way above Toyota levels.

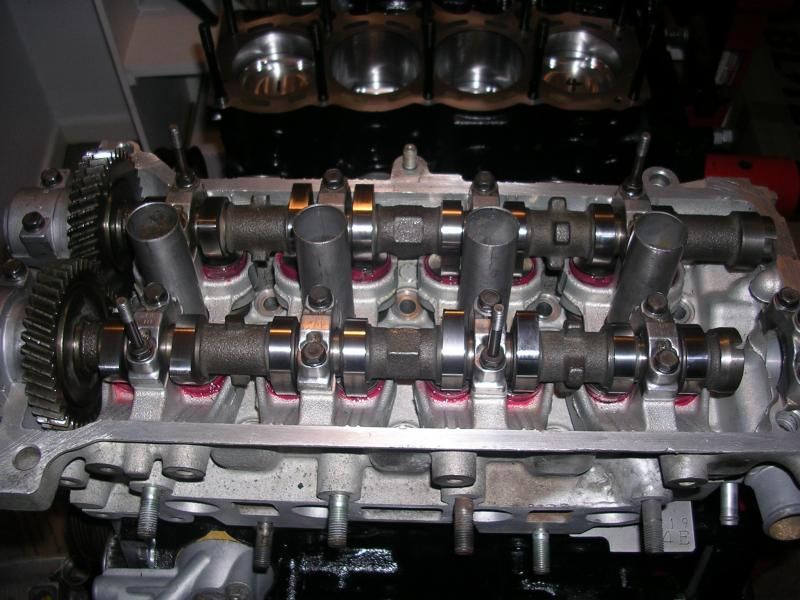

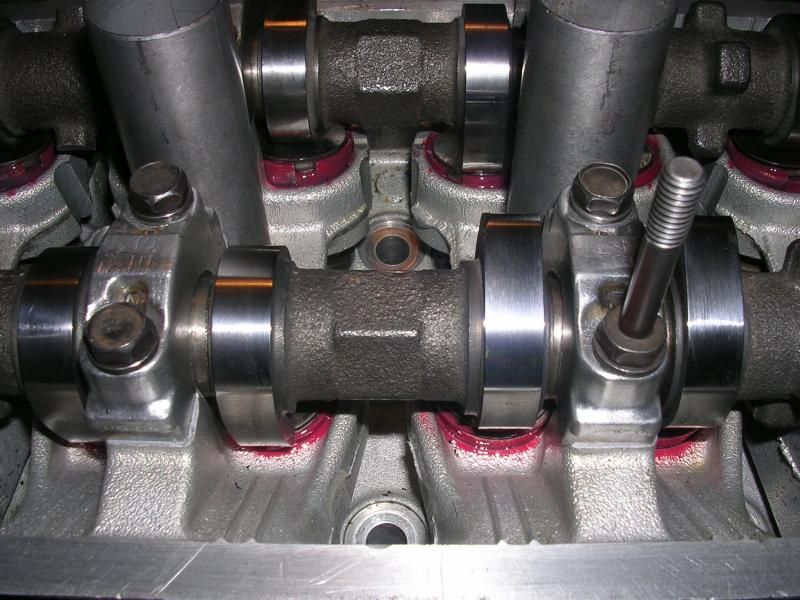

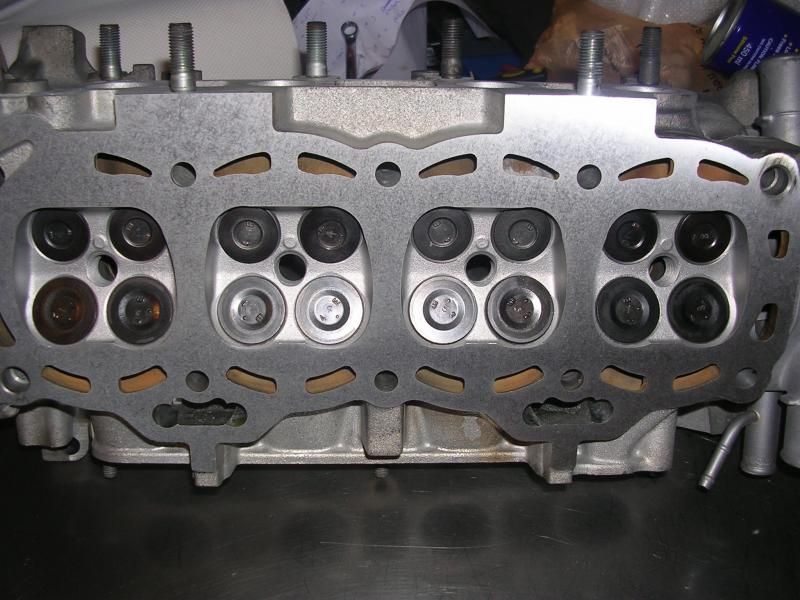

The head was totally rebuilt, guides were ok so left, head cleaned, valve seats re-cut with 3 angle valve job and reground. Lifters polished, Cams shimmed and journals and lobes polished.

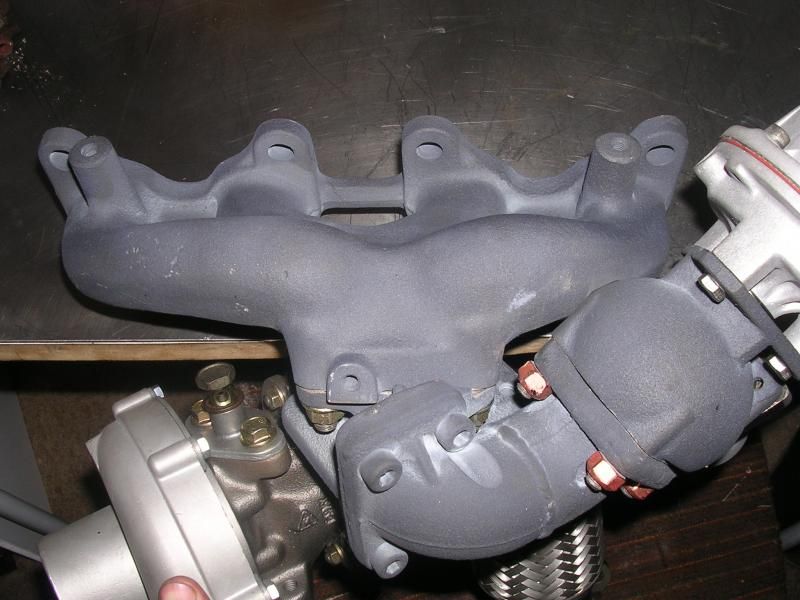

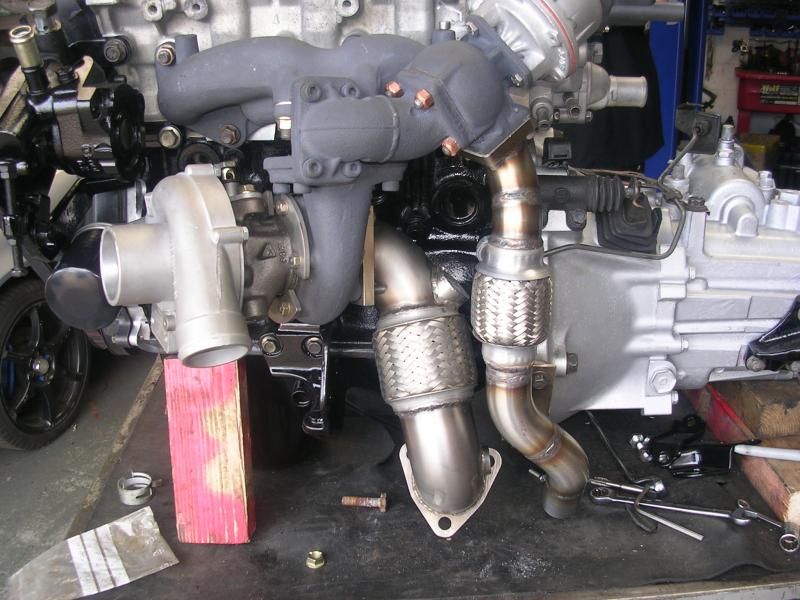

The turbocharger he's selected was an item i rebuilt for myself but didn't ever fit, an extremely rare Blitz K2-220r Turbocharger. Totally build from the ground up with all new blitz seals, turbo rebuild by AET turbo for us with a 12month guarantee. The manifold is a ported Jam Racing Cast unit and all external hot parts have been ceramic coated by Zircotech in performance black. This is the same material and company that coat the F1 exhaust systems. Downpipe was totally built by me as the original blitz mild steel unit has fell apart

The engine arrived in the car in a bit of a sorry state, the engine had a rattle, it smoked and there was debit in the sump. Upon strip down I found that the rattle was caused by the previous company that rebuilt his head hadn't tensioned the camshaft cogs. The smoking was down to a very poorly turbocharger. And if it hadn't had been for this other issue the engine was actually perfect. BUT, unfortunately while the car was off the road because of these faults Nik had been carrying out some modifications, FMIC, Intake and bought a nicely powder-coated black rocker cover. Well the person he purchased it from had shot-blasted it and not told Nik. So upon fitting and running all the shot stuck under the baffles in rocker cover worked themselves loose, got into the oil system and destroy the engine.

Unfortunately the block and some parts of the head were totally destroyed and un-usable. The crank had been worn so badly it was beyond even repair by regrinding, the bores were badly scored to much for a re-bore, And the head and cams suffered light scoring that thankfully was fixable.

The engine was completely rebuild built from the ground up. Using my own design Wiseco Forged Pistons, Scat Conrods, ARPs, Metal Headgasket, ACL Bearings. The block was first ultrasonic tested for thickness and locally ex-rayed for internal crack structure. bored and honed using my own torque plate, to simulate head stresses and coolant at 82 degrees passed around the block to simulate block expansion under temperature. This ensures all the cylinders are all perfectly round not when sat on a stand but when under operation and running in the car. Pistons are measured and cylinders bored to that cylinder seeing all pistons are very slightly different sized. So #1 piston now goes into #1 cylinder. Again this maintains perfect piston to cylinder clearances. All static and rotationally parts balanced to 1/3rd of a gram which is way above Toyota levels.

The head was totally rebuilt, guides were ok so left, head cleaned, valve seats re-cut with 3 angle valve job and reground. Lifters polished, Cams shimmed and journals and lobes polished.

The turbocharger he's selected was an item i rebuilt for myself but didn't ever fit, an extremely rare Blitz K2-220r Turbocharger. Totally build from the ground up with all new blitz seals, turbo rebuild by AET turbo for us with a 12month guarantee. The manifold is a ported Jam Racing Cast unit and all external hot parts have been ceramic coated by Zircotech in performance black. This is the same material and company that coat the F1 exhaust systems. Downpipe was totally built by me as the original blitz mild steel unit has fell apart