D.I.Y Head Job

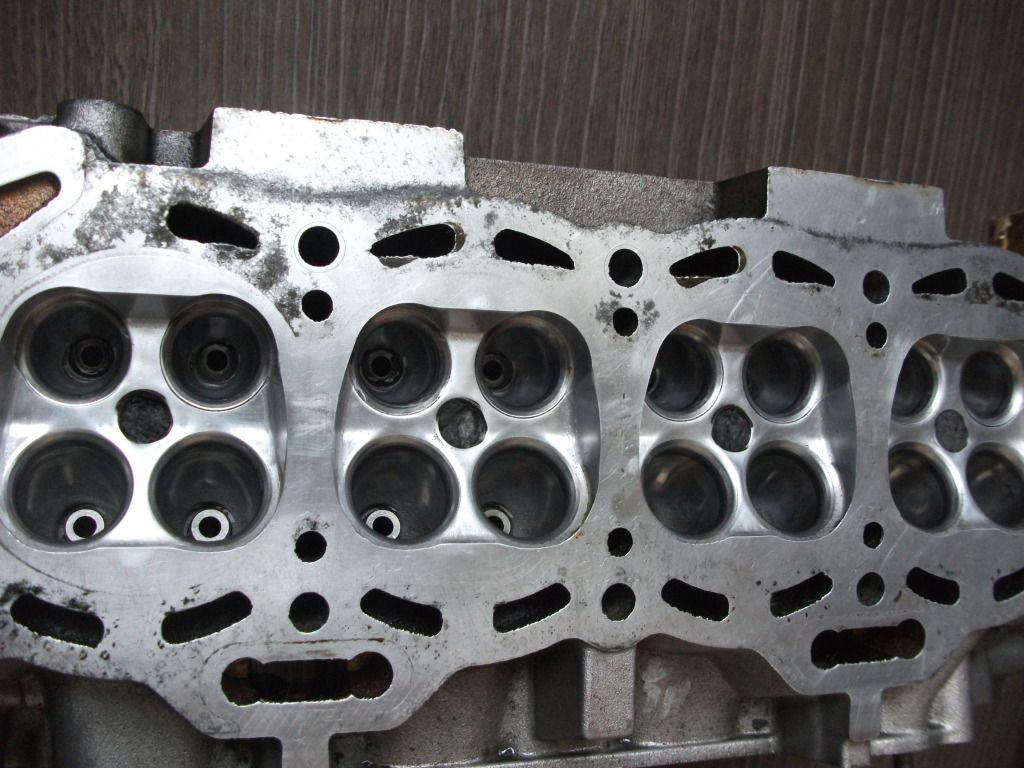

Before:

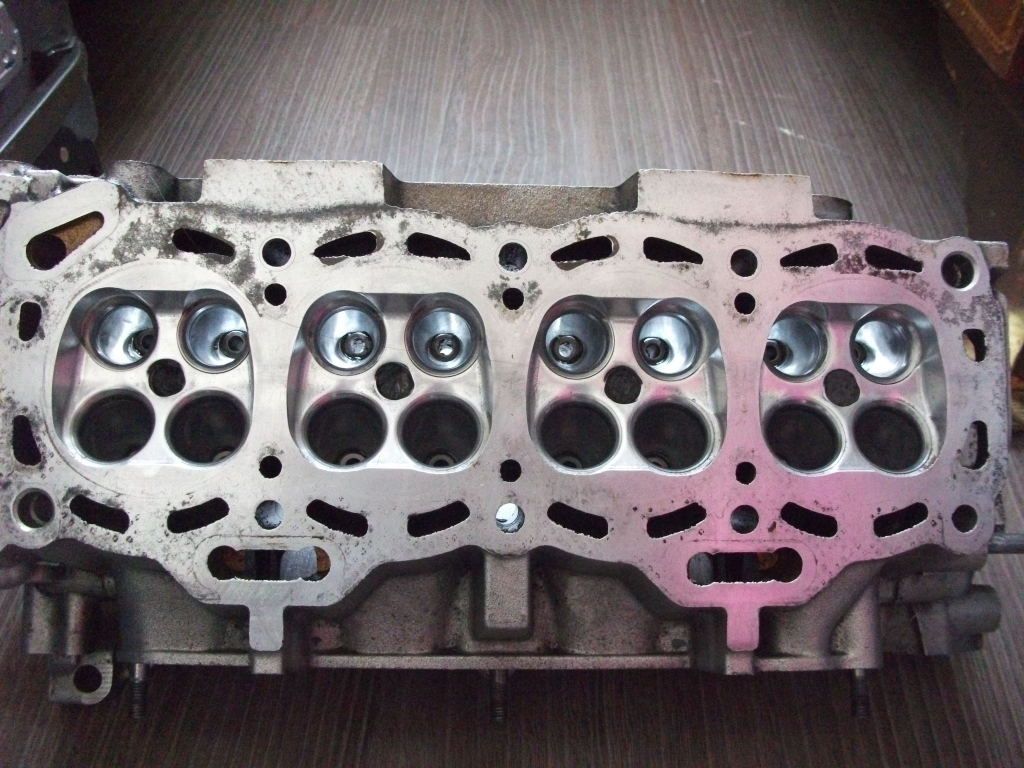

After the moon came back around:

Aim for this head was minimal material removal for use in a street, fast road setup and to give good response from the turbo.

I used a rotary tool with lots of consumables.

Sanding bands ( i think 160 or 200 grit) to take casting marks off and generally clean up the chambre, valve throats and ports.

Next was a wipe over all with scotchbrite 800 to take off the sharp tall peaks. At this point it already starts to look good, but next is rubbing time, big time with various grit sandpaper and WD40.

I started with 1200 grit wet with WD40 and dry. Get some rubbing music going, i like the wubba wubbuba type, really gets me rubbing. Just make sure you cover all surface area. Once you finished with the 1200, you want to clean the mess off completely, i used brake cleaner so that the surface is ready to attack with the next finer sand paper 1500 grit. Continue this wet and dry with each grit paper, 2000 and 2500.

After the rubbing is done with the sand paper i used a cutting compound to take of the micro peaks that can still remain present which can drastically upset flow via stalling or chocking the air in addition to causing turbulance.

Finally i used a small polishing wheel on the end of the rotary tool with a polish to finish off and jobs a good one. Unfortunantley i have not yet access to a flowbench, but results speak for themself when you drive the car, it will be a much more efficient flowing cylinder head. I am gonna do a cylinder head for a friend which will be used for drag with more material removed for a much higher volume of airflow.

Edit: The intake has also been worked on, will take and upload pics and the cylinder head has now been port matched both sides and chambres blueprinted.