Lets look at the situation.

Toyota's VVT (Variable Valve Timing) and VVT-i(Variable Valve Timing with intelligence). Both systems are not like VTEC. They do not affect lift. They affect duration. Also VVT isn't always on, again unlike VTEC. It turns on and off.

VVT: VVT is found on the 1st and 2nd generation 4AGE20v. VVT advances the cam 15 degrees on activation. This means once ON the cam ratchets forward 15degrees. The Silvertop engine (gen1) VVT comes ON at 4400rpm and is OFF at 6000rpm. On the Blacktop (gen2) VVT is dynamic. It operates on several parameters of which the two major ones are throttle and rpm. Once past 60% throttle VVT kicks in. The operational rpm range for VVT is 3000rpm to 6000rpm, however VVT has a dynamic range of 1600rpm to 6500rpm. It will differ due to too many variables to list, but these are the peaks at which it operates. The car may opt to end the VVT cycle at 5500rpm or extend it to 6200rpm, just depends. It has a matrix in the stock ECU it uses to compute. The reason VVT ratchets back at 6000rpm+ is because the valve overlap moves from short (torque creation) to wide (max flow). Discussion on how it affects the powerband later.

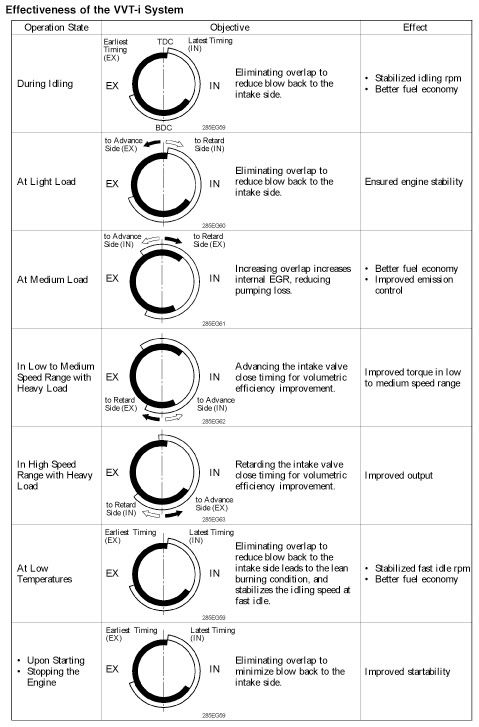

VVTi: Is now the standard basic Toyota VVT system. It can be found on all Toyota's modern engines like the 3SGE, N and JZ series engines, in Dual form on the Altezza SXE10 3SGE. The cam lift side of things was added to 2ZZ to create VVTL-i. VVTi built on the dynamic nature of VVT. Its job is to maintain the smallest valve overlap to build torque in any condition. What this system does is not simply go to a fixed position, but move the cam to any position +/-15edgrees for 30degrees of actuation. This means that if the car wants 22degrees at 4000rpm at one point and 9degrees at the same exact rpm in a different situation it can do so.

So the fundamental differences is that VVT goes to a fixed point when activated, and VVTi doesn't. VVTi dances back and forth as its needed within its operational parameters.

VVT can have three states of operation, ON, OFF and CONSTANT. Remember VVT turns itself on and off by the stock ECU, but you can bypass that signal and turn it on when you feel like, turn it off, or have it on constantly from any rpm point. VVTi, when given a constant signal (aftermarket), goes to its maximum forward position 15degrees and stays there, eliminating its dynamic programming.