@andycam06 its a thin line thats all i'll say :lol: , Yeah should have it done by the summer hopefully.

Thanks for the comments lads appreciate it.

Not much to update started a new job I've been very busy.

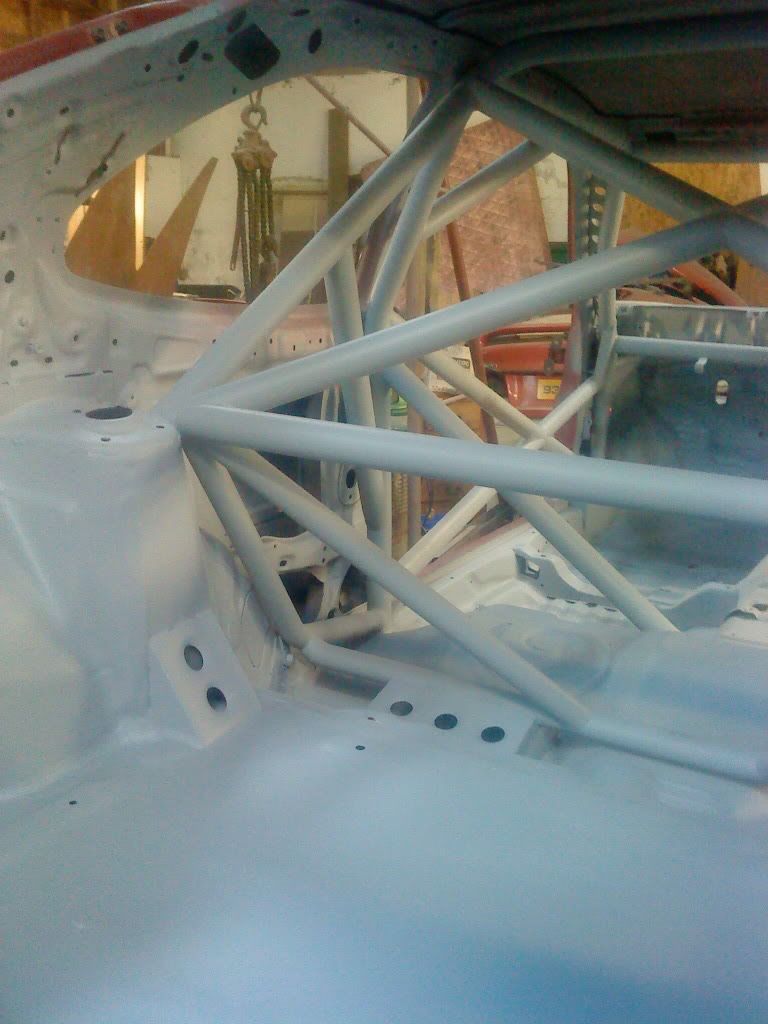

All the door and boot lid shuts are now done,along with the inside of the doors, bonnet and behind the rear bumper etc. All panel and door gaps are done. The trollie was a little on the high side so I had to cut the angle brackets down to lower the car closer to the ground as Hugh ( bodywork guy) couldn't reach the roof properly. But its starting to look more like a car again.

Also when I was down there there was a guy getting his ae92 restored excuse the wheels there being replace with oem ae92 wheels as this car i say is going to be concors juging by the engine detail.

And this is the mintest ae86 i've ever seen 56k geniune mies all original body, lovely car just drool!

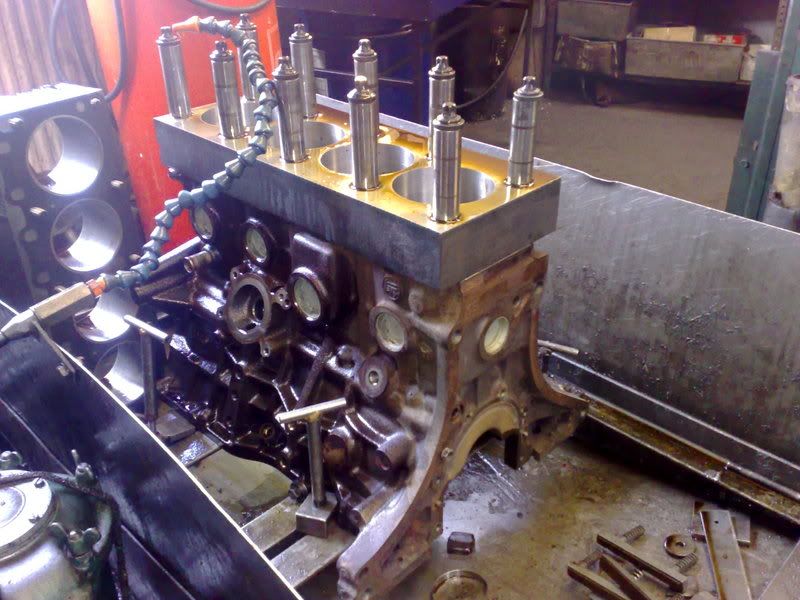

Started to make a engine stand,

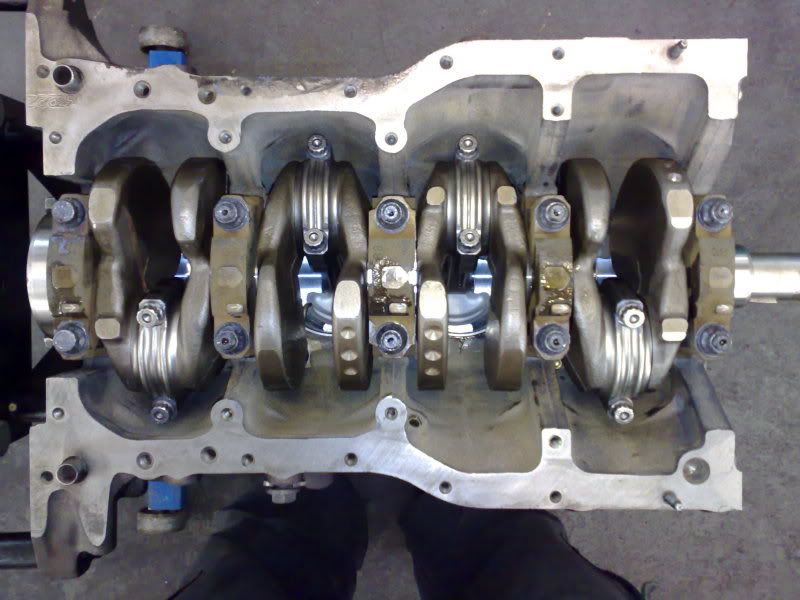

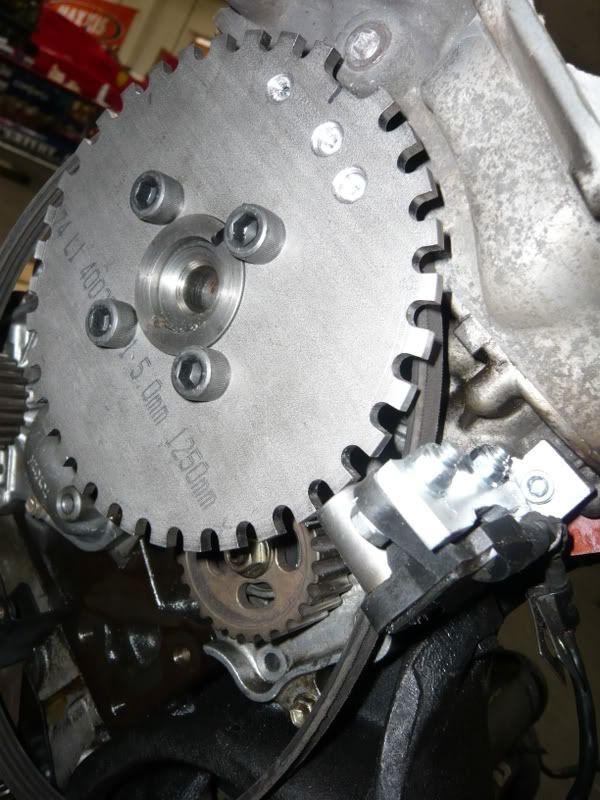

All universal stands you have to remove the 3s flywheel and clutch to get to mount to the stand like this.

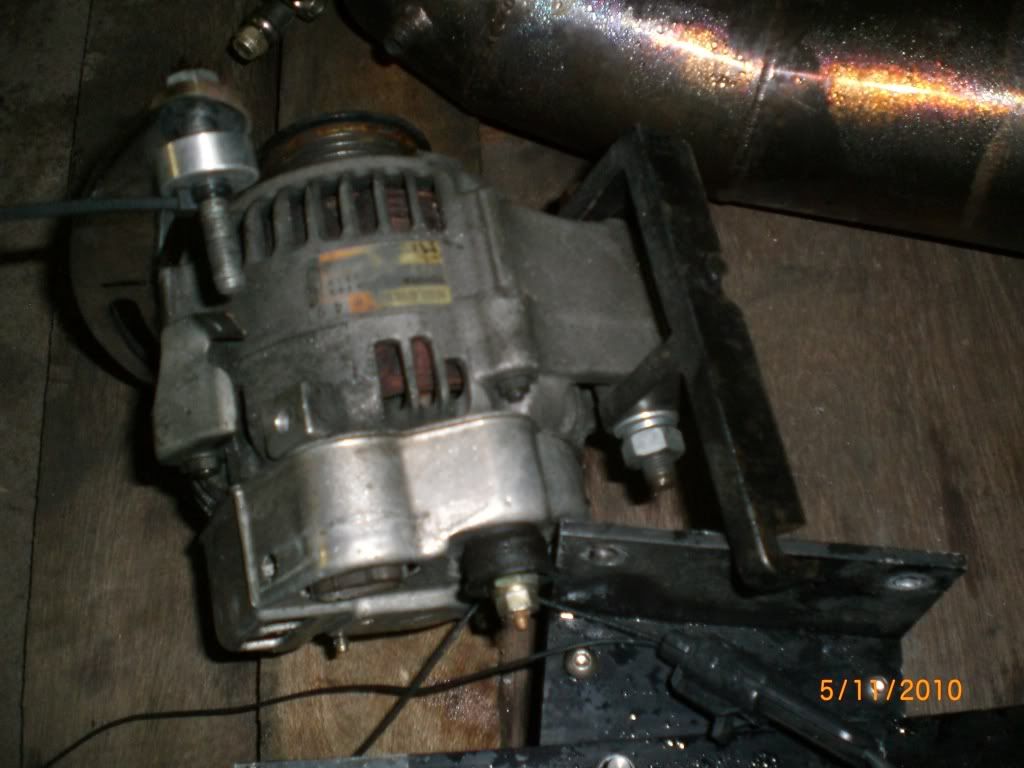

But I wanted a stand where by I could mount it up complete with Fly/clutch but as to mount the starter to turn the engine and possibly run the engine on the stand if i wish to so I had a spare mr2 turbo box kicking around with no diff in it so i took the bellhousing side off and give it to Brendanlez and he took some big chucks of aluminium of it with his big milling machine and he kindly give it a blast clean too. Cheeers Brendan.

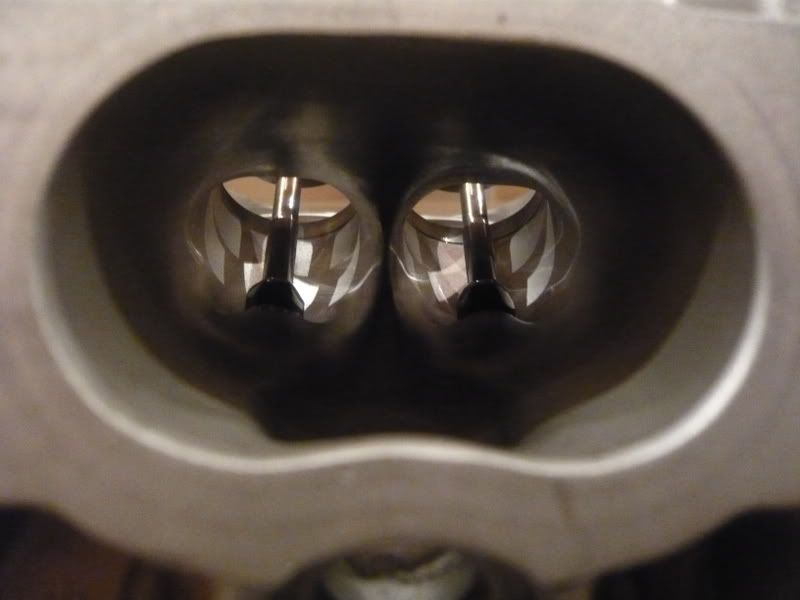

Then i set it up on the small miling machine and started tiding it up, with a 25mm end mill.

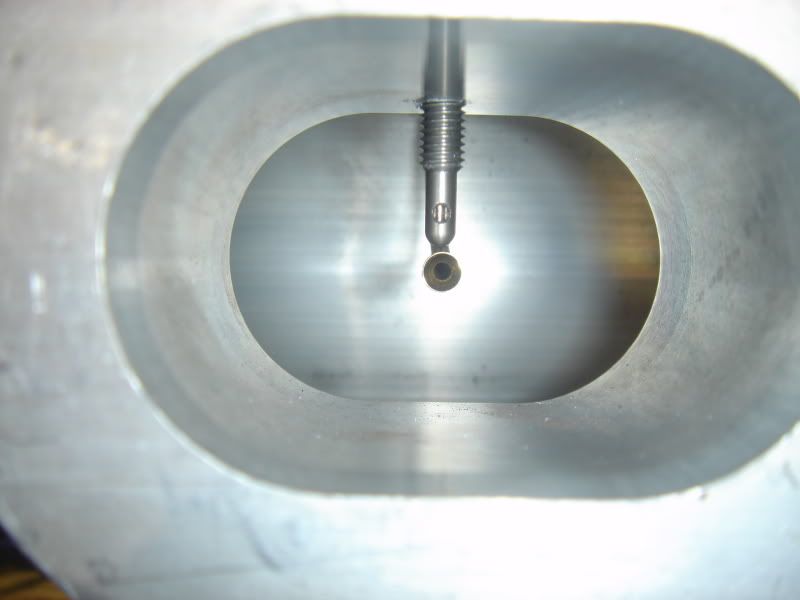

Then it to the saw to cut the diff side cover of the bellhousing

Then this needs a 12mm plate welded onto it and 4 holes drilled into the new plate and it can mount to my stand.