It's been a while since I updated this thread due to work commitments, I'll try to bring everything up to speed with this one.

New rotor arm versus old cracked one:

A fresh distributor cap was recommended too :

Here is a closer view of why I advised a fresh cap, new one first:

And the old one in comparison:

It's always stormy when Wee John and I work at an engine conversion and today was no different..

FMIC on:

Bumper modified to accomodate FMIC:

Bumper on:

The end of the turbo accelerator cable differs from the NA one. Pretty sure it's just a case of screwing the bolt across after removing the bung but I only realised this once the old cable was out. The turbo one fits hunky dory though.

Once engine oil pressure was achieved by cranking her over (kinglead and injector plugs disconnected) we went for the first start. She started first turn of the key. B)

Initial idle was around 2k rpm due to a few pipes left open and the engine being cold but once up to temperature she settled down to a happy idle speed. The only thing of note was an oil leak from below the turbo (possible hard oil feed pipe but needs investigated).

Bonnet on:

But to close it we will need to mess about with the intercooler piping from the turbo to intercooler. Wee John had a brain wave on solving this and improving the flow greatly so we'll do that next time he's here.

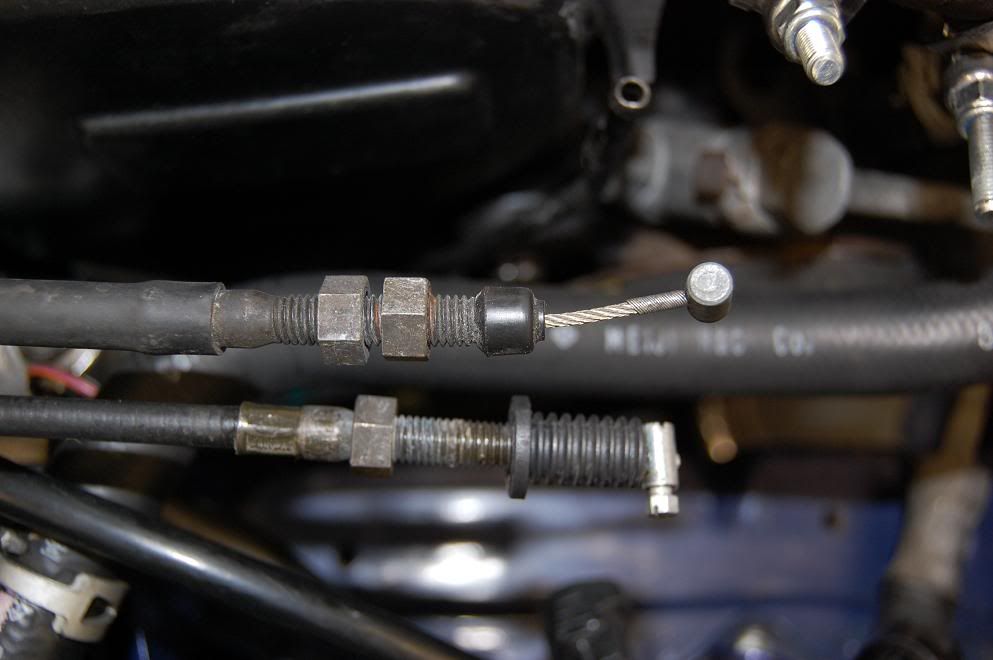

Also swapped across the brake servo pipe from the turbo model for safety sake. The servo uses an air feed from the intake mani to operate. This one way valve stores the required air (in vacuum I think) just incase it is not available. This can be the case when on boost and without this valve present you may find a hesitation in braking effect.

Safety first!

Turbo pipe versus NA version:

That all important valve:

A few pics of the nearly finished article:

And all the turbo's together. Sounds weird to hear that Phil huh?

Since then I've received the dump valve adaptor which will make things much easier:

Refitted the driveshafts. Your passenger side one needed both boots repacked and secured by the way Phil:

Exhaust fitted (forgot to get pics) and wheels all back to one type:

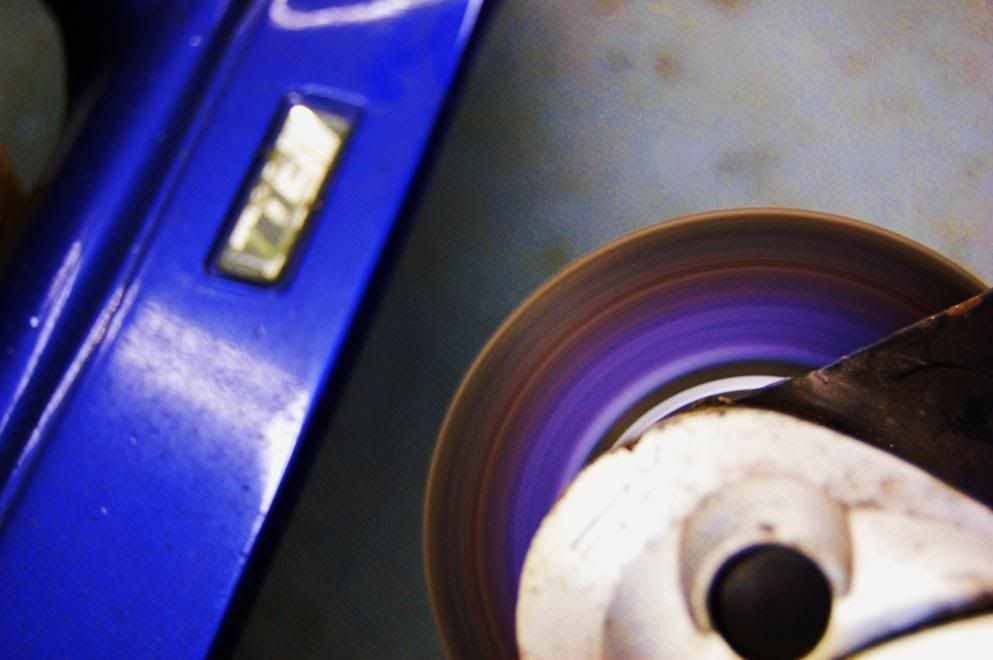

Inspected the oil feed pipe leak and I'm glad I did before driving her anywhere:

Looked to be coming from the metal flange at the top so I undid the bolts for the metal feed/return and reached up to remove it - the rubber return pipe fell apart. Must have been split in the impact that the donor car took. I drained three and a half litres from the donor engine so I'd guess that she didn't run too far after the crash thankfully.

A new pipe is due into Toyota tomorrow at a cost of £4 so that's another box ticked.

Successful story so far and I'm looking forward to getting that corner of my garage back soon.

Left to do on the list we have:

Fit new oil return pipe.

Fill gearbox with oil.

Source suitable pipe for dumpvalve.

Modify FMIC piping.

Source coolant bottle.

Install boost controller and gauge.

Other than that we're set. It's just a case of some little silly things delaying the process at the end which is to be expected. Cannot wait to see how she boosts.