gorganl2000

Lifer

is the stock ignition system "square wave",,,if not, what is it??

i have an electronic boost controller (eboost2) which stated that to run the rpm connection i need a square wave connection..i need to know if this can work with the stock starlet system...here are the exact words from the manual

"""""""The e-Boost2 is able to accept an RPM signal in the form of a square wave that is switching between 0V and 3.5-12 v

The following points should be followed to connect your RPM signal to the negative terminal of an ignition coil. NOTE: Caution should

be exercised when connecting to the negative terminal of an ignition coil and Turbosmart recommends an ECU connection where

possible. IMPORTANT! The RPM signal should not be connected to a coil of a capacitive discharge ignition (CDI) system.

- Check the signal from the negative terminal is a square wave that is switching between switching between 0V and 3.5-12 volts with

an appropriate meter.

- Connect the wire RPM signal wire from the e-Boost2 to the negative terminal of an ignition coil."""""""""

i assume this is IGF on the EP91 ECU connection (#3 pin on 26 plug - IGF Ignition Feedback from the Ignitor-Coil), but when i connect to this wire, the eboost rpm display reads randomly/incorrectly

has anyone got the eboost2 rpm reading to work on their ep82/91??

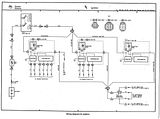

below are the EP91 ignition wires according to the ecu pin out (26 plug)

pin 3 IGF Ignition Feedback from the Ignitor-Coil

pin 4 NE Part of the IIA (Intergrated Ignition Assembly) (RPM)

pin 5 G1 Distributor

pin 17 G- Distributor Crank Angle

pin 18 G2 Distributor

pin 22 IGT Ignition Timing

any help appreciated...maybe i used the wrong pin, but pin 3/IGF works great on my gizzmo shift light

i have an electronic boost controller (eboost2) which stated that to run the rpm connection i need a square wave connection..i need to know if this can work with the stock starlet system...here are the exact words from the manual

"""""""The e-Boost2 is able to accept an RPM signal in the form of a square wave that is switching between 0V and 3.5-12 v

The following points should be followed to connect your RPM signal to the negative terminal of an ignition coil. NOTE: Caution should

be exercised when connecting to the negative terminal of an ignition coil and Turbosmart recommends an ECU connection where

possible. IMPORTANT! The RPM signal should not be connected to a coil of a capacitive discharge ignition (CDI) system.

- Check the signal from the negative terminal is a square wave that is switching between switching between 0V and 3.5-12 volts with

an appropriate meter.

- Connect the wire RPM signal wire from the e-Boost2 to the negative terminal of an ignition coil."""""""""

i assume this is IGF on the EP91 ECU connection (#3 pin on 26 plug - IGF Ignition Feedback from the Ignitor-Coil), but when i connect to this wire, the eboost rpm display reads randomly/incorrectly

has anyone got the eboost2 rpm reading to work on their ep82/91??

below are the EP91 ignition wires according to the ecu pin out (26 plug)

pin 3 IGF Ignition Feedback from the Ignitor-Coil

pin 4 NE Part of the IIA (Intergrated Ignition Assembly) (RPM)

pin 5 G1 Distributor

pin 17 G- Distributor Crank Angle

pin 18 G2 Distributor

pin 22 IGT Ignition Timing

any help appreciated...maybe i used the wrong pin, but pin 3/IGF works great on my gizzmo shift light