Well lads after alot of thinking gone into this i have decided to build my 99 teg r with the drag scene getting bigger and after watching a few good cars up at it i said it was time to join in the fun

My car is being built by JStoneRacing also help from TDP, i reckon hopefully we can get some decent times during the year.

The car was started yesterday by getting a full respray (nice to have it looking the part aswel as being quick) this was done by Jstone and hav to say very happy so far thanks lads great work .

Here is a short spec of what the car is getting at the moment, this may change as the build go's on!

Engine

b16a

built bottom end with eagle rods,

wossner pistons,

arp headstuds and big end bolts,

ctr crank,

lightly mod'ed head,

custom TDP block gard,

Gearbox

stock box with LSD

Turbo

TME EVO VI TD05 with custom manifold and down pipe

wheels and tyres

15'' wheels with toyo r888 for the moment

Performance

350+hp

11's on the strip (we hope )

new shoes

and here is the TDP eng build for those of you who are not elite bt

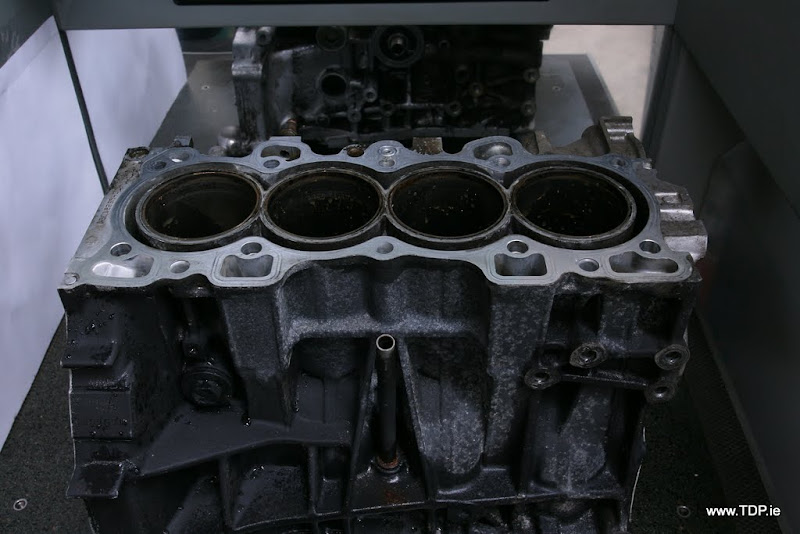

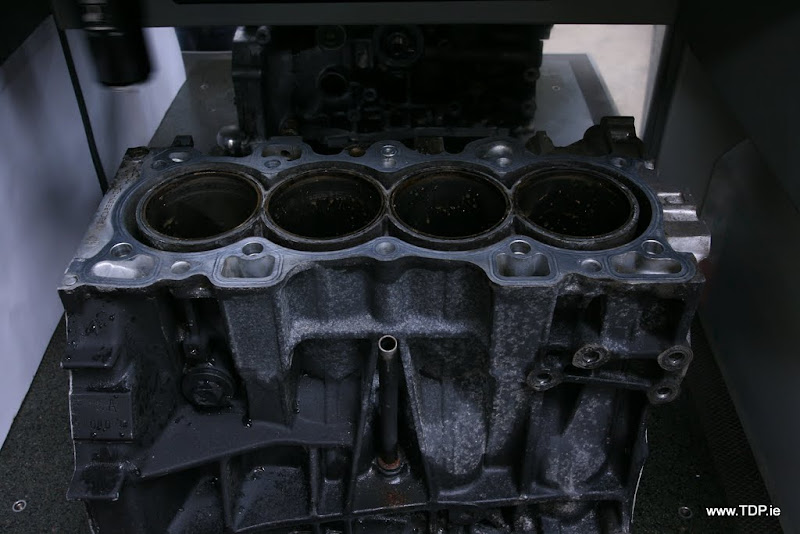

We are building this B16a to be capable of producing in excess of 450+ bhp.

For this reason we need to do certain things to stop the cylinder pressures killing the engine.

The first thing is to reinforce the top of the block and bores with a custom TDP block guard.

To do this we use our Digitizing/Scanning machine to measure the relevant parts of the block.

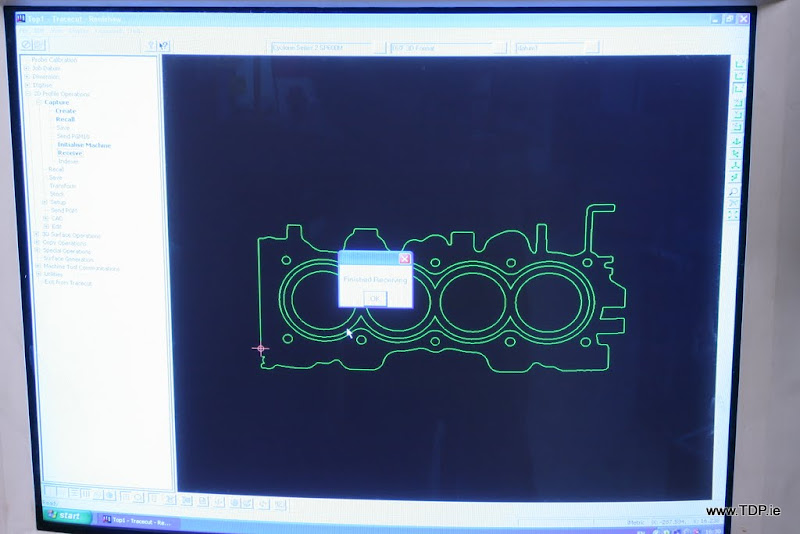

The scanned data is exported as a DXF file.

The DXF file is imported and the relevant geometries are extracted as the Block guard is designed.

[IMGIMG]http://lh5.ggpht.com/_FCe34KJd9-c/S4qjhI_CDGI/AAAAAAAAGow/77Hhq0KNFNM/s800/BlockGuard-1.jpg[/IMG]

Then the 2D CAD is sent to the 3d Solid modeling SW.

This is 100% accurate of what the block guard will look like.

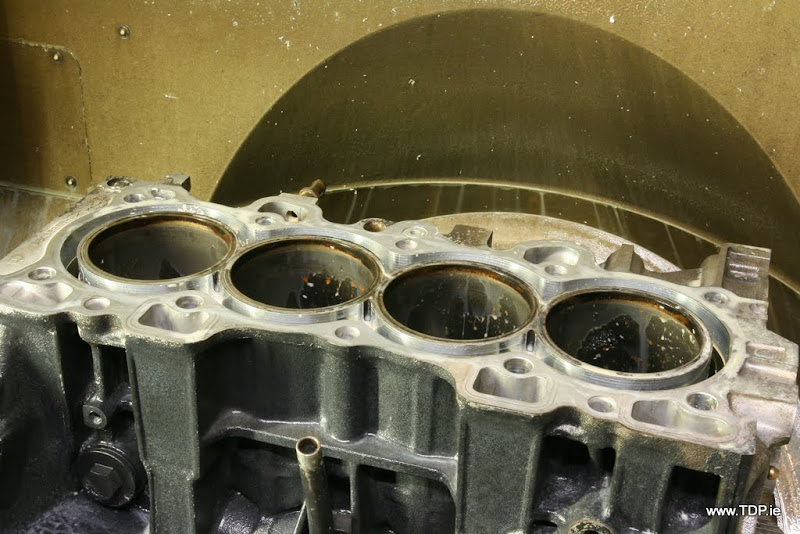

The next thing that need to be done is to machine the top of the block to accept the guard. The block is cast and the shape cannot be guaranteed so we machine between 0.25mm and 0.5mm of to make sure we have a consistent surface for the guard to spread the load against once on place.

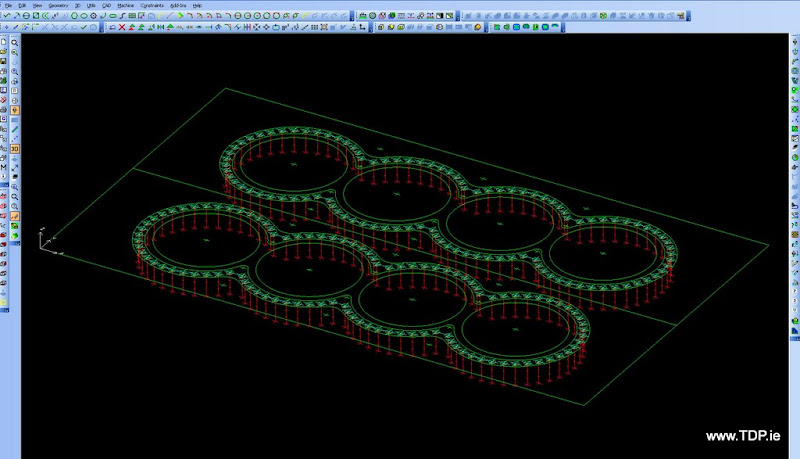

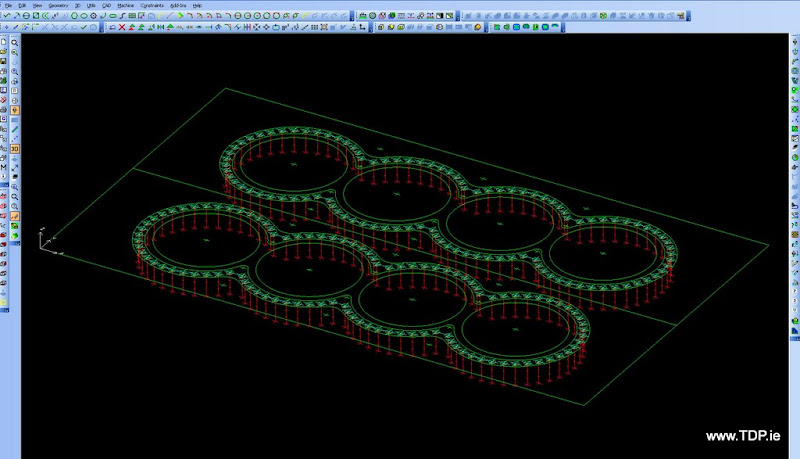

The first thing is to use the cad data we have to produce tool paths for the CNC machine to follow.

This is done in Alphacam V6 CAM package.

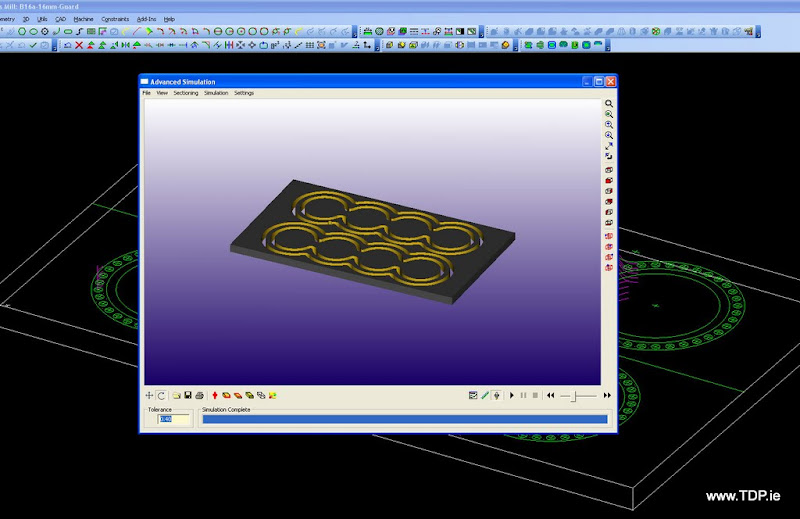

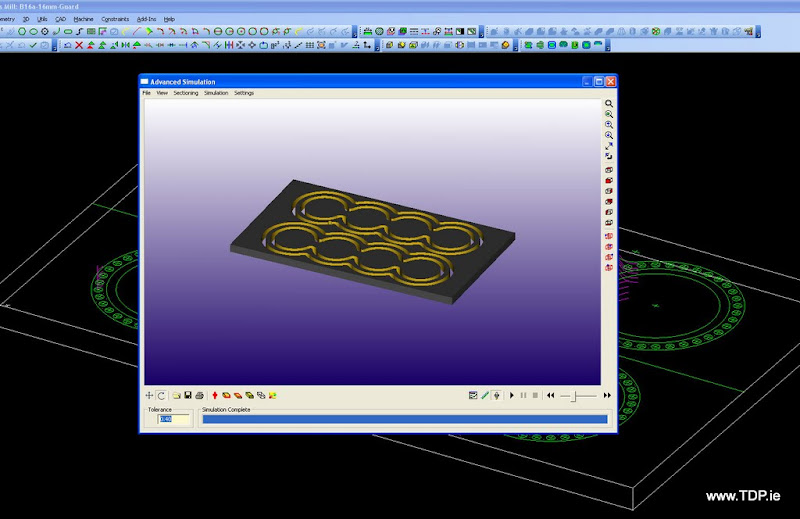

Then the toolpaths are simulated to make sure there are no mistakes.

Then the block is bolted to the Deckel Maho DMU 70 Evolution High Speed Machining Center.

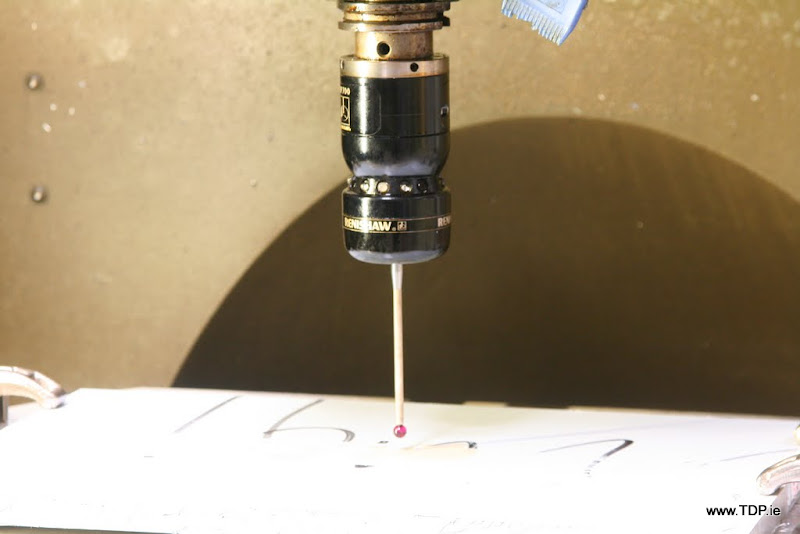

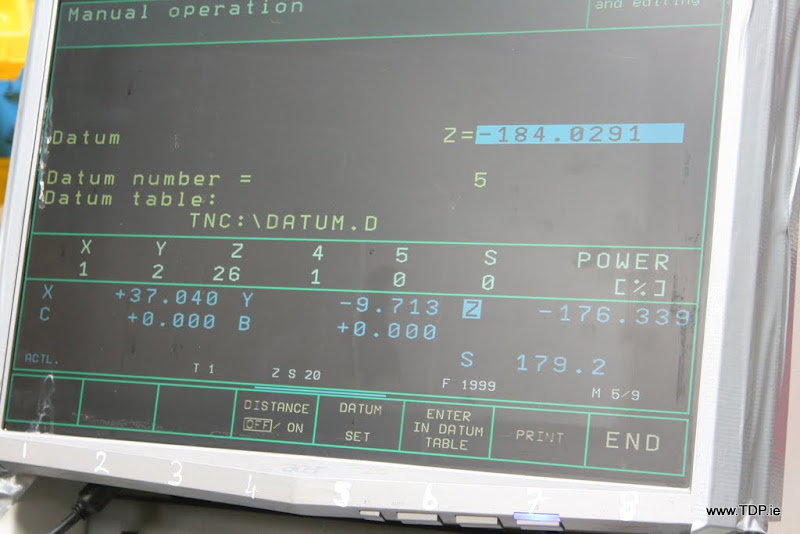

The Renishaw MP700 Strain gauge probe is used to measure the block exact position in X,Y,Z and for rotation also.

http://lh5.ggpht.com/_FCe34KJd9-c/S4...0/IMG_8489.JPG[/url]

Then the 6mm solid carbide cutter is calibrated in the Renishaw NC1 laser tool setter.

[IMG]http://lh4.ggpht.com/_FCe34KJd9-c/S4q5K7wejjI/AAAAAAAAGqo/P2DPE1_BG04/s800/IMG_8490.JPG

Now the block can be machined.

You can see that the block is now ready for the block guard to be fitted.

New mishimoto rad great quality very happy with it and big thanks to Kevtegra great service will be dealing with you again bt

and big thanks to Kevtegra great service will be dealing with you again bt and also thanks to adriano for dropping it down to me

and also thanks to adriano for dropping it down to me

Thanks lads .

Making the block guard.

We start off with the billet and clamping it to the machine.

We fit the plate machine fixture to the DMU70eVo.

Next we put ground spacers to support the billet to allow through machining.

The 16 mm 7075T6 alu plate is them clamped onto the table.

The Renishaw MP700 Probe is used to measure the plates position relative to the machine.

The New 8 mm Cutter is setup in the holder.

The Drill and Milling Cutter are measured on the machine using the laser tool setter.

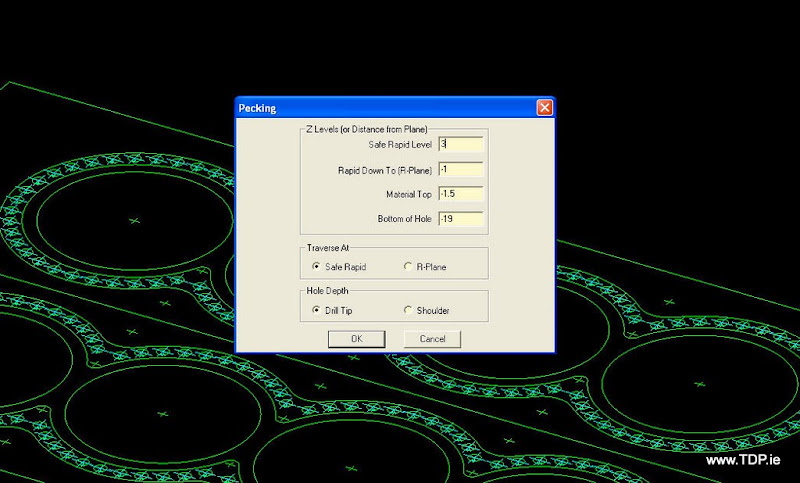

The 2D CAD data is Imported from Solidworks to Alphacam V6.

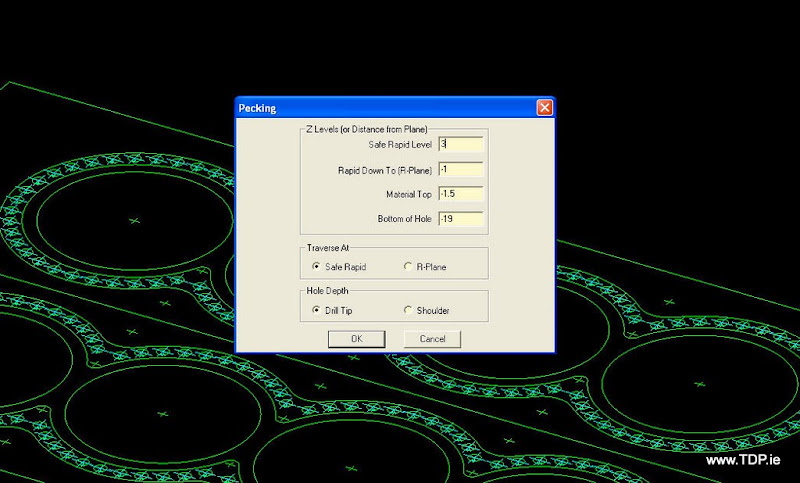

The Tool is chosen and the operation information programed.

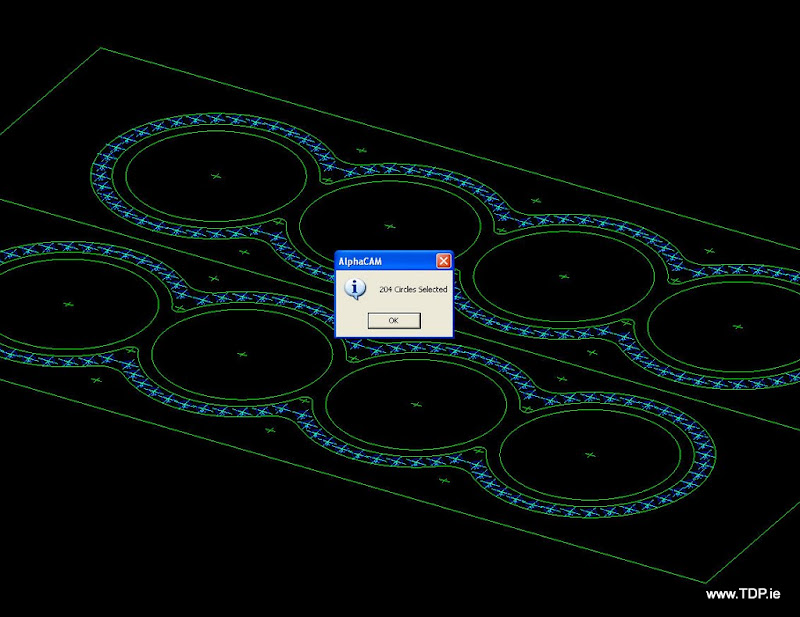

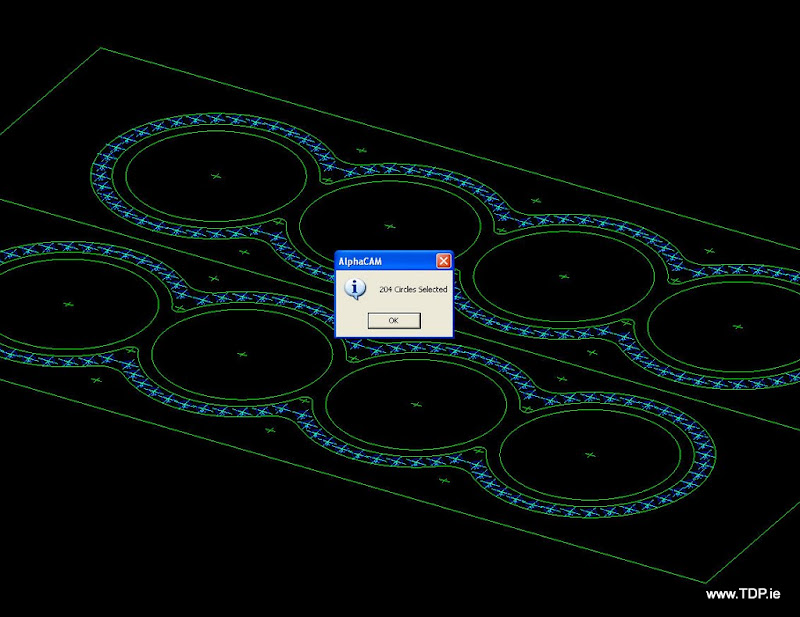

The 204 holes are selected

The 5.1mm Drill Bit is selected and cut depths programed.

Roughing mill passes are added to remove some of the material allowing for finishing.

The program is verified in a Virtual machine before the program is transmitted to the machine.

The 10 mm Spot Drill marls out the hole positions for the 5mm Drill. This avoids any drill wandering as drill are very flexible.

The 5.1 mm Drill then Drills the 204 hole all the way through the parts.

The 8mm Cutter then cuts out the Inside of the part.

Finally the finishing passes are programed and verified.

The finishing passes are run.

The finished block guard on top of the block ready for fitting.

My car is being built by JStoneRacing also help from TDP, i reckon hopefully we can get some decent times during the year.

The car was started yesterday by getting a full respray (nice to have it looking the part aswel as being quick) this was done by Jstone and hav to say very happy so far thanks lads great work .

Here is a short spec of what the car is getting at the moment, this may change as the build go's on!

Engine

b16a

built bottom end with eagle rods,

wossner pistons,

arp headstuds and big end bolts,

ctr crank,

lightly mod'ed head,

custom TDP block gard,

Gearbox

stock box with LSD

Turbo

TME EVO VI TD05 with custom manifold and down pipe

wheels and tyres

15'' wheels with toyo r888 for the moment

Performance

350+hp

11's on the strip (we hope )

new shoes

and here is the TDP eng build for those of you who are not elite bt

We are building this B16a to be capable of producing in excess of 450+ bhp.

For this reason we need to do certain things to stop the cylinder pressures killing the engine.

The first thing is to reinforce the top of the block and bores with a custom TDP block guard.

To do this we use our Digitizing/Scanning machine to measure the relevant parts of the block.

The scanned data is exported as a DXF file.

The DXF file is imported and the relevant geometries are extracted as the Block guard is designed.

[IMGIMG]http://lh5.ggpht.com/_FCe34KJd9-c/S4qjhI_CDGI/AAAAAAAAGow/77Hhq0KNFNM/s800/BlockGuard-1.jpg[/IMG]

Then the 2D CAD is sent to the 3d Solid modeling SW.

This is 100% accurate of what the block guard will look like.

The next thing that need to be done is to machine the top of the block to accept the guard. The block is cast and the shape cannot be guaranteed so we machine between 0.25mm and 0.5mm of to make sure we have a consistent surface for the guard to spread the load against once on place.

The first thing is to use the cad data we have to produce tool paths for the CNC machine to follow.

This is done in Alphacam V6 CAM package.

Then the toolpaths are simulated to make sure there are no mistakes.

Then the block is bolted to the Deckel Maho DMU 70 Evolution High Speed Machining Center.

The Renishaw MP700 Strain gauge probe is used to measure the block exact position in X,Y,Z and for rotation also.

http://lh5.ggpht.com/_FCe34KJd9-c/S4...0/IMG_8489.JPG[/url]

Then the 6mm solid carbide cutter is calibrated in the Renishaw NC1 laser tool setter.

[IMG]http://lh4.ggpht.com/_FCe34KJd9-c/S4q5K7wejjI/AAAAAAAAGqo/P2DPE1_BG04/s800/IMG_8490.JPG

Now the block can be machined.

You can see that the block is now ready for the block guard to be fitted.

New mishimoto rad great quality very happy with it

Thanks lads .

Making the block guard.

We start off with the billet and clamping it to the machine.

We fit the plate machine fixture to the DMU70eVo.

Next we put ground spacers to support the billet to allow through machining.

The 16 mm 7075T6 alu plate is them clamped onto the table.

The Renishaw MP700 Probe is used to measure the plates position relative to the machine.

The New 8 mm Cutter is setup in the holder.

The Drill and Milling Cutter are measured on the machine using the laser tool setter.

The 2D CAD data is Imported from Solidworks to Alphacam V6.

The Tool is chosen and the operation information programed.

The 204 holes are selected

The 5.1mm Drill Bit is selected and cut depths programed.

Roughing mill passes are added to remove some of the material allowing for finishing.

The program is verified in a Virtual machine before the program is transmitted to the machine.

The 10 mm Spot Drill marls out the hole positions for the 5mm Drill. This avoids any drill wandering as drill are very flexible.

The 5.1 mm Drill then Drills the 204 hole all the way through the parts.

The 8mm Cutter then cuts out the Inside of the part.

Finally the finishing passes are programed and verified.

The finishing passes are run.

The finished block guard on top of the block ready for fitting.