goldenvtr

Member +

So ive started to making my loom for the Link G3 ecu

so far ive wired to COPs and a few sensors but im at the point now where i need to fit a trigger wheel, as im removing the stock ignition setup and dizzy cap end etc for neatness.

my plan was to use a design i saw on Mikey B's project a while ago.

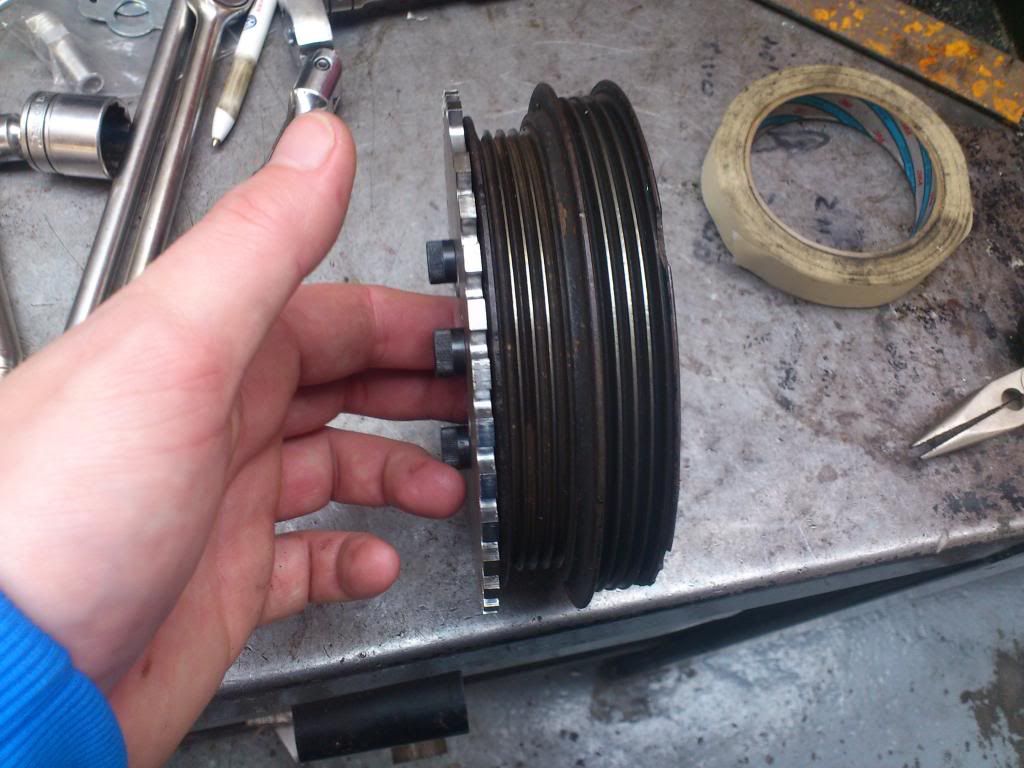

welding on a 36-1 trigger wheel to the crank and custom making a bracket to hold the VR sensor.

whos done this? and lets get some pics up please

so far ive wired to COPs and a few sensors but im at the point now where i need to fit a trigger wheel, as im removing the stock ignition setup and dizzy cap end etc for neatness.

my plan was to use a design i saw on Mikey B's project a while ago.

welding on a 36-1 trigger wheel to the crank and custom making a bracket to hold the VR sensor.

whos done this? and lets get some pics up please