You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine cutting out?

- Thread starter Schism

- Start date

Frankieflowers

Member +

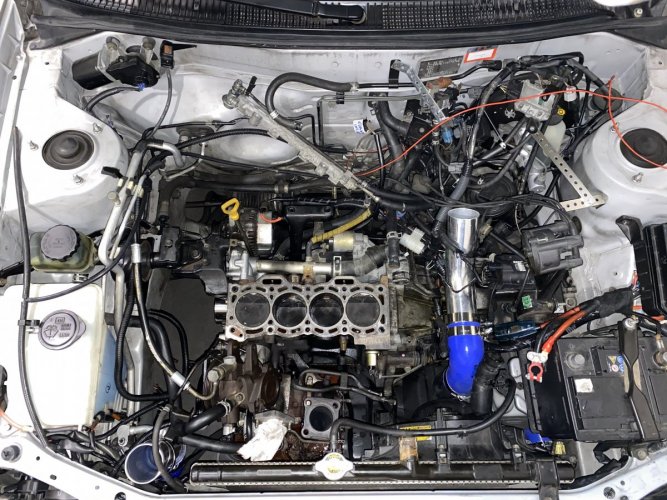

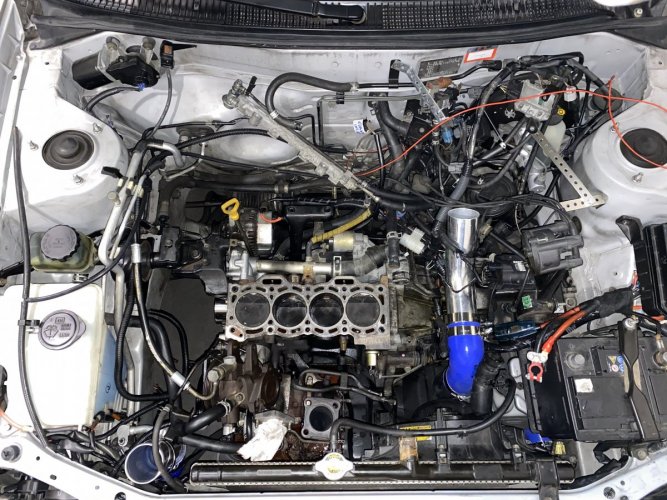

Is it possible to get furl cut due to boost creep caused by a stock manifold output fix like this one in the picture? The car was running perfectly before we had to get the cylinder off to get welded. Now it blows like a thick baloon. We checked if turbo bolts were tight and all looks fine. But the engine isn’t running like before. Besides the weird noise, reaching mid range 3000 RPM the engine hesitates. Like a 2 stroke running lean. Plug sparks are quite light brown. I changed the thermostat with a Paseo 86* to lower cylinder temp and it should be better. What happened? FMIC pipes haven’t been touched.

Frankieflowers

Member +

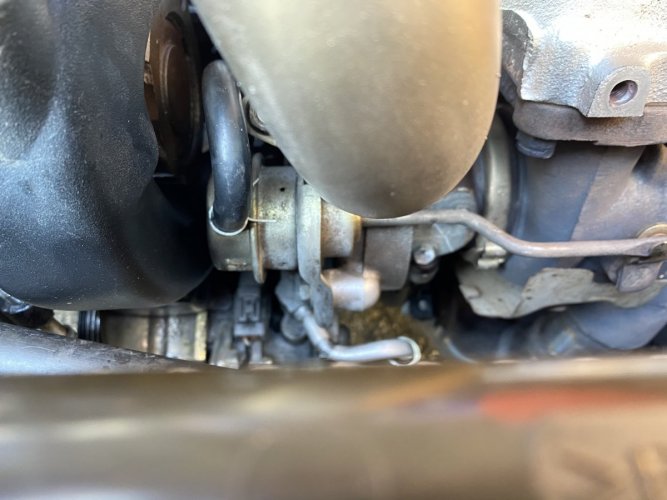

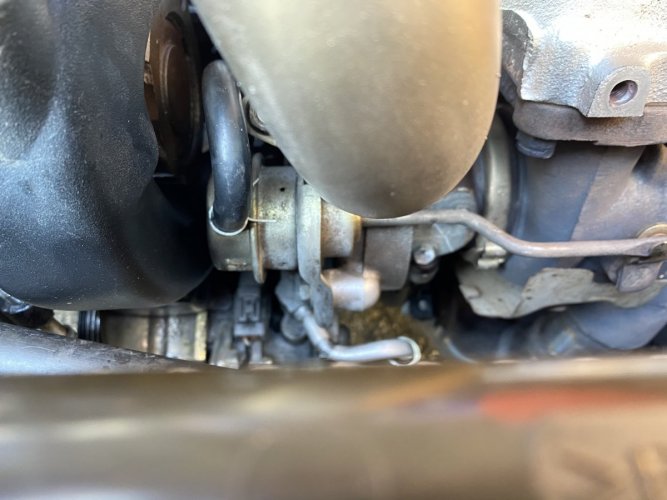

It’s in good state. We welded to micro cracks that you can see in the picture. The rest was good. We modified the turbo side as you can see. Problem is the engine doesn’t run like before. It is not a matter of mechanics because the cylinder head has been properly fixed and it runs smooth. Apparently I am witnessing a fuel cut in mid range acceleration around 3000 RPM. If I go fuel gas the engine dies. It should be the ECU cutting to avoid too much air in the throttle. It’s suspicious because I don’t think that modifying the exhaust manifold would give that extra performance to cause problems to a custom map. What do you think about it? Could it be the map sensor? It worked a week before so why shouldn’t it work anymore? I went to check the two hoses and I blew some air with my mouth in the filter that goes to the map sense. It’s quite stuck. Could it be that too Cuz lean carburetion and white brown spark plugs? The noise I hear around 3000 RPM sounds like constant weird tribulation noise that probably comes from the modification we did at the manifold?What state is the gasket in?

Frankieflowers

Member +

Frankieflowers

Member +

I honestly am not sure if there is an exhaust manifold leak. We just put it back on with the new gasket. The only thing that changed from before is that we went in the cross on the turbo side to make it smooth. I don’t know if this is causing a problem. Matter of the fact is that the engine isn’t working like before. I am going to change the hose with its filter on the map sensor because I have another one from the other engine I replaced. The spark plugs were brown white before and it was already the signal that carburetion was running lean. Too much air. What to do about it? when I accelerate and give more gas the engine slows down. It’s the exact inverse reaction that was happening before. Logically it means that there is too much air and we need more fuel. The fuel injectors have been cleaned and tested with 12 V signal to open the ports and go through with some liquid to check if they were working properly. this means I am not sure it’s a fuel problem. The WALBRO 255 I installed months ago has been chosen in order to change the echo and map the card to get more horsepower. This means more fuel. So why isn’t it working properly with a custom set up? I really don’t know what happened. I was the one to get all the hoses and electric parts of the engine so that my partner would be able to work around the cylinder head to take it off. We didn’t touch anything and of course only the turbo has been moved around to get it off the exhaust manifold. Water is OK. Oil is OK. The wastegate hasn’t been touched and it’s air hoses as well.Porting the manifold shouldn't have a massive effect on performance (in my experience anyway). Are you definitely hearing/feeling an exhaust leak at the manifold?

If you think it's ECU fuelcut check for fault codes. Fuelcut usually flags up as an overboost.

do you have a picture of the air hoses connections behind the turbo cold side? I have a suspect that something might be wrong there. The other suspect I have is that fuel pump isn’t working properly. Problem is I don’t have the gouge to check fuel pressure.

my brother told me to find TOYOBD1 hardware and software to check the parameters but there is no way to find it. I also subscribed on the Facebook group but nobody is selling it. That would be precious to see all the parameters I need with the custom ECU. Do you think that someone has it and can borrow it or sell it to me? Is there something similar on the market I can use to see check fuel/air parameters?

Jay

Admin

Chances are that if it was running fine before the work then it's related to the work that was done. This should rule out stuff like fuel pump and the likes.

If its not boosting then the plugs will be white. They run lean until the turbo kicks in so if you aren't seeing boost the plug colour will be a false flag.

I would be retracing your steps of the work done, inspect anything that was touched in case its a simple pipe mix up.

Forgive me but I've forgotten - Does your diagnostic port still work? Might give you a steer instead of messing around with ECU parameters (which you can't change on a Glanza anyway).

If its not boosting then the plugs will be white. They run lean until the turbo kicks in so if you aren't seeing boost the plug colour will be a false flag.

I would be retracing your steps of the work done, inspect anything that was touched in case its a simple pipe mix up.

Forgive me but I've forgotten - Does your diagnostic port still work? Might give you a steer instead of messing around with ECU parameters (which you can't change on a Glanza anyway).

Frankieflowers

Member +

I will try to go backwards again and see what could have gone wrong. Yes I know the computer cannot be touched. The diagnostic port works but there is no error. I will check again. All hoses and replace the map sensor filter.Chances are that if it was running fine before the work then it's related to the work that was done. This should rule out stuff like fuel pump and the likes.

If its not boosting then the plugs will be white. They run lean until the turbo kicks in so if you aren't seeing boost the plug colour will be a false flag.

I would be retracing your steps of the work done, inspect anything that was touched in case its a simple pipe mix up.

Forgive me but I've forgotten - Does your diagnostic port still work? Might give you a steer instead of messing around with ECU parameters (which you can't change on a Glanza anyway).

Frankieflowers

Member +

Yes we did when we took the EFI off to replace the metal clamp. It’s smooth and apparently blades are fun. Let’s consider that the turbo was perfect before we did the work and it couldn’t get broken sitting there. Of course getting the turbo off and sending it to the shop for refurbishing would be the best but I already spent quite a lot of money to fix this cylinder head crack. I was hoping to enjoy the car for a little bit before spending other money.Also have you checked the turbo blades for play/damage?

WhiteOverGoldMK1GT

Member +

"The car is modified beyond spec, but as it was a private sale im not fully aware of the full list of mods. The previous owner claimed it put out about 210BHP on high boost with no FCD"

you have been lied to.

while a 4efte can do this, all day every day, it will cut like a horse being slapped and kicking you in the head, especially At that hp with no ecu / tune OR at the very least a fcd/ RRFPR

it can be dangerous, but addicting and fun

----> i would not trust anything any seller tells or shows you until proven by receipts of work. <----

but i digress buying a car is magical in person and you forget the important things.

everyone suffers from this, it is why you bring someone impartial to a sale of a vehicle, they will see what you cannot

the first issue you described on page 1 is boost cut. on a stock ecu, the turbo kicks in Fairly moderately at 3k as there usually is not any real controller on there to help it, on a ported setup like you have, it will only get there that much exponentially faster and will basically slam itself into whatever boost level as fast as it is able to

i would go so far as to say that your Blow off valve wont be big enough to deal with that anymore, if you have one

Heavy Cut happens at around 14 psi. best to dial it back to 13.8 / 13.7 to be safe when flooring it.

i used a GFB G-FORCE 3, electronic controller to do this, best workaround possible besides going further.

( boost cut at 13.7, gain at 0, sensitivity at 0 or 1 if you buy that controller )

yeah it is a right pain to get around. the culprit for this is the following

Your -----> "ported ct-9 turbo with hks actuator" <----

a pretty bad combo. good for quick boost, but stock they just cant deal with it

the downpipe should make it worse as well, as the extra flow rather violently makes the car lack control with its boost, even if the actuator accoutns for it, you will get a massive spike in boost

your issue is specifically the actuator, wind it back / Out a few spins, whatever the opposite it is now, and try again.

For some perspective, i have been here, but worse.

when i bought my starlet, without knowing much, it had that same actuator on it.

the very first drive, i drove my starlet over 700 kilometres,

It was the best drive i have ever had in a car, 100% Raw Crack induced power.

despite the following being hidden from me

Somehow, it drove home with a cut off 02 sensor / wiring, fucked tps, and barely functioning Throttle body, every vac leak possible, missing throttle gasket, missing downpipe gaskets, and a extremely blown turbo with almost 20psi of boost running through it, clogged catalytic converter, every oil leak possible, The wrong piston's for the bore size at 74mm pistons in a 74.5 bore, broken coolant sensor, broken air idle circuit,

got roughly 220 k's to a tank, filled multiple times in that trip, and the fuel cut was horrendous, running that much psi really quickly hits the cut limit, the equivalent of running headfirst into a wall.

This car would very soon to that time, catch fire and die, and be revived over 2 years costing a stupid amount.

that amount now amounts to 50k :/

issue 2,

right so if it dies with a sudden sensor condition state change, ie throttle, sudden load, etc then you have a sensor problem. mine did that too. Throttle PoS sensor issue either dying, being miscalibrated, and combined with a dead coolant ecu sensor, either dying or throwing the wrong voltage, most of the time this issue does not throw a code,

mine had a massive dead zone on throttle, small or large it would start dying until a certain rpm past 3200, at which point it flew.

the oem ecu is extremely resilient, and will run with basically a few sensors working, ( coolant, tps, and distributor home signal )

it will attempt to do what is asked of it until the engine explodes, does not matter how bad it gets, damn reliable toyota's

it is very possible the combination of the actuator and porting of multiple items has led to the turbo being more capable and widely uncontrollable than the ecu can account for, in which case you should attempt to run wastegate pressure on another actuator OR less wound up on your current actuator, and see if that fixes the issue. try to run under 9 psi, see what happens when floored.

if you do not have a boost gauge, get one immediately

you have been lied to.

while a 4efte can do this, all day every day, it will cut like a horse being slapped and kicking you in the head, especially At that hp with no ecu / tune OR at the very least a fcd/ RRFPR

it can be dangerous, but addicting and fun

----> i would not trust anything any seller tells or shows you until proven by receipts of work. <----

but i digress buying a car is magical in person and you forget the important things.

everyone suffers from this, it is why you bring someone impartial to a sale of a vehicle, they will see what you cannot

It’s in good state. We welded to micro cracks that you can see in the picture. The rest was good. We modified the turbo side as you can see. Problem is the engine doesn’t run like before. It is not a matter of mechanics because the cylinder head has been properly fixed and it runs smooth. Apparently I am witnessing a fuel cut in mid range acceleration around 3000 RPM. If I go fuel gas the engine dies. It should be the ECU cutting to avoid too much air in the throttle. It’s suspicious because I don’t think that modifying the exhaust manifold would give that extra performance to cause problems to a custom map. What do you think about it? Could it be the map sensor? It worked a week before so why shouldn’t it work anymore? I went to check the two hoses and I blew some air with my mouth in the filter that goes to the map sense. It’s quite stuck. Could it be that too Cuz lean carburetion and white brown spark plugs? The noise I hear around 3000 RPM sounds like constant weird tribulation noise that probably comes from the modification we did at the manifold?

the first issue you described on page 1 is boost cut. on a stock ecu, the turbo kicks in Fairly moderately at 3k as there usually is not any real controller on there to help it, on a ported setup like you have, it will only get there that much exponentially faster and will basically slam itself into whatever boost level as fast as it is able to

i would go so far as to say that your Blow off valve wont be big enough to deal with that anymore, if you have one

Heavy Cut happens at around 14 psi. best to dial it back to 13.8 / 13.7 to be safe when flooring it.

i used a GFB G-FORCE 3, electronic controller to do this, best workaround possible besides going further.

( boost cut at 13.7, gain at 0, sensitivity at 0 or 1 if you buy that controller )

yeah it is a right pain to get around. the culprit for this is the following

Your -----> "ported ct-9 turbo with hks actuator" <----

a pretty bad combo. good for quick boost, but stock they just cant deal with it

the downpipe should make it worse as well, as the extra flow rather violently makes the car lack control with its boost, even if the actuator accoutns for it, you will get a massive spike in boost

your issue is specifically the actuator, wind it back / Out a few spins, whatever the opposite it is now, and try again.

For some perspective, i have been here, but worse.

when i bought my starlet, without knowing much, it had that same actuator on it.

the very first drive, i drove my starlet over 700 kilometres,

It was the best drive i have ever had in a car, 100% Raw Crack induced power.

despite the following being hidden from me

Somehow, it drove home with a cut off 02 sensor / wiring, fucked tps, and barely functioning Throttle body, every vac leak possible, missing throttle gasket, missing downpipe gaskets, and a extremely blown turbo with almost 20psi of boost running through it, clogged catalytic converter, every oil leak possible, The wrong piston's for the bore size at 74mm pistons in a 74.5 bore, broken coolant sensor, broken air idle circuit,

got roughly 220 k's to a tank, filled multiple times in that trip, and the fuel cut was horrendous, running that much psi really quickly hits the cut limit, the equivalent of running headfirst into a wall.

This car would very soon to that time, catch fire and die, and be revived over 2 years costing a stupid amount.

that amount now amounts to 50k :/

issue 2,

right so if it dies with a sudden sensor condition state change, ie throttle, sudden load, etc then you have a sensor problem. mine did that too. Throttle PoS sensor issue either dying, being miscalibrated, and combined with a dead coolant ecu sensor, either dying or throwing the wrong voltage, most of the time this issue does not throw a code,

mine had a massive dead zone on throttle, small or large it would start dying until a certain rpm past 3200, at which point it flew.

the oem ecu is extremely resilient, and will run with basically a few sensors working, ( coolant, tps, and distributor home signal )

it will attempt to do what is asked of it until the engine explodes, does not matter how bad it gets, damn reliable toyota's

take the advice given, Double check everything you have touched, every wire, every sensor, hose, vac line, All grounds, bolts etc, every single thing on that engine, it is so easy to screw up things, even i did so a few weeks ago with a vac line, and have many times before, outside perspective is hugely helpful, knowledge comes from learning how things fail.Yes we did when we took the EFI off to replace the metal clamp. It’s smooth and apparently blades are fun. Let’s consider that the turbo was perfect before we did the work and it couldn’t get broken sitting there. Of course getting the turbo off and sending it to the shop for refurbishing would be the best but I already spent quite a lot of money to fix this cylinder head crack. I was hoping to enjoy the car for a little bit before spending other money.

Your lean condition can be caused by not tuning the ecu. stock ecu cannot be tuned, and only learns so far,I honestly am not sure if there is an exhaust manifold leak. We just put it back on with the new gasket. The only thing that changed from before is that we went in the cross on the turbo side to make it smooth. I don’t know if this is causing a problem. Matter of the fact is that the engine isn’t working like before. I am going to change the hose with its filter on the map sensor because I have another one from the other engine I replaced. The spark plugs were brown white before and it was already the signal that carburetion was running lean. Too much air. What to do about it? when I accelerate and give more gas the engine slows down. It’s the exact inverse reaction that was happening before. Logically it means that there is too much air and we need more fuel. The fuel injectors have been cleaned and tested with 12 V signal to open the ports and go through with some liquid to check if they were working properly. this means I am not sure it’s a fuel problem. The WALBRO 255 I installed months ago has been chosen in order to change the echo and map the card to get more horsepower. This means more fuel. So why isn’t it working properly with a custom set up? I really don’t know what happened. I was the one to get all the hoses and electric parts of the engine so that my partner would be able to work around the cylinder head to take it off. We didn’t touch anything and of course only the turbo has been moved around to get it off the exhaust manifold. Water is OK. Oil is OK. The wastegate hasn’t been touched and it’s air hoses as well.

do you have a picture of the air hoses connections behind the turbo cold side? I have a suspect that something might be wrong there. The other suspect I have is that fuel pump isn’t working properly. Problem is I don’t have the gouge to check fuel pressure.

my brother told me to find TOYOBD1 hardware and software to check the parameters but there is no way to find it. I also subscribed on the Facebook group but nobody is selling it. That would be precious to see all the parameters I need with the custom ECU. Do you think that someone has it and can borrow it or sell it to me? Is there something similar on the market I can use to see check fuel/air parameters?

it is very possible the combination of the actuator and porting of multiple items has led to the turbo being more capable and widely uncontrollable than the ecu can account for, in which case you should attempt to run wastegate pressure on another actuator OR less wound up on your current actuator, and see if that fixes the issue. try to run under 9 psi, see what happens when floored.

if you do not have a boost gauge, get one immediately

Last edited:

Frankieflowers

Member +

Turbo boost is stable as everything is normal. If there is a leak it isn’t cutting boost. Is it possible that the fuel pump is damaged or there is something wrong with the fuel pressure regulator on the rail?Also have you checked the turbo blades for play/damage?

Frankieflowers

Member +

Thank you for your reply. I have a boost gouge. What exactly should I do? could you elaborate so that I can understand? I’m new to this. Thanksshould attempt to run wastegate pressure on another actuator OR less wound up on your current actuator, and see if that fixes the issue

Frankieflowers

Member +

I will do check again. I appreciate it. First thing I will do will be to open up the pretension of the blow off valve spring. I wanna see what happens.Double check everything you have touched, every wire, every sensor, hose, vac line, All grounds, bolts etc, every single thing on that engine, it is so easy to screw up things, even i did so a few weeks ago with a vac line, and have many times before, outside perspective is hugely helpful, knowledge comes from learning how things fai

WhiteOverGoldMK1GT

Member +

hook the boost gauge anywhere you can attach it with a single boost vacuum t, looks like thisThank you for your reply. I have a boost gouge. What exactly should I do? could you elaborate so that I can understand? I’m new to this. Thanks

the reference on the turbo works great for this.

Turbo outlet -----> T <--- Wastegate reference

boost gauge

attach a vacuum line between the turbo and the wastegate reference, straight to a boost gauge, purchase one, any terrible one will do for testing

basically the pretension on that wastegate arm, can cause the turbo to have a gain setting higher than whats needed.I will do check again. I appreciate it. First thing I will do will be to open up the pretension of the blow off valve spring. I wanna see what happens.

WhiteOverGoldMK1GT

Member +

if the fuel pump were damaged the car would not run at all, as even the slightest amount of mis-Flow in the lines will stall the car,Turbo boost is stable as everything is normal. If there is a leak it isn’t cutting boost. Is it possible that the fuel pump is damaged or there is something wrong with the fuel pressure regulator on the rail?

hence the fact most cars have a regulator, keeps pressure up regardless to an extent during power runs or similar, they do not usually fail while stock or slightly power'd up,

still, the easiest way to test this is to ----> SAFELY <---- remove a fuel line somewhere on the filter or nearby and place the end of the fuel line removed in a container, make sure its decently sized, and then put the key in, BUT DO NOT START IT, only put it on the accessory power to prime the pump, a few seconds should be enough to tell. key on, 1 or 2 seconds, key off. again do not start the car.

watch the flow amount, if it seems slow / a small amount comes out, it is likely your fuel filter is dirty and old, replace it if so, very common with starlets

post a photo of the fuel amount int he container here, for a quick answer to if it is clogged or not, also a photo of the fuel filter as well.