Jay

Admin

Thank Yu guys When we closed the cylinder head cover the 4E hole was perfectly aligned and the crank was in zero position as it should be. This is a hunter percent. Using the timing gun everything runs perfectly so apparently the issue is elsewhere. About the turbo, we touched the turbine and it’s really smooth with no play. I started to think that maybe evolve retouch the process to change the gaskets and the rectification of the head basement might have change something. Usually the compression rate goes in little bit higher but it shouldn’t change much. Saturday morning I will go to the tuner and he will check the cylinder compression to see if the valves are leaking. I will check the map sensor voltage today. I am worried that the little filter on the hose might be feeling. I don’t know where to find one and if there is a different one on the market that might fit.

regarding the wideband. I am not an expert of that field. What exactly should I do? Thank you.

Was worth checking the timing marks even if you didn't find anything. Gets them off the list of possibilities.

Compression will increase slightly if the head has been skimmed. Even if this is the case it would make the engine more responsive. Doubt this is your issue tbh. I've turbocharged 4EFE's and they are well out of spec.

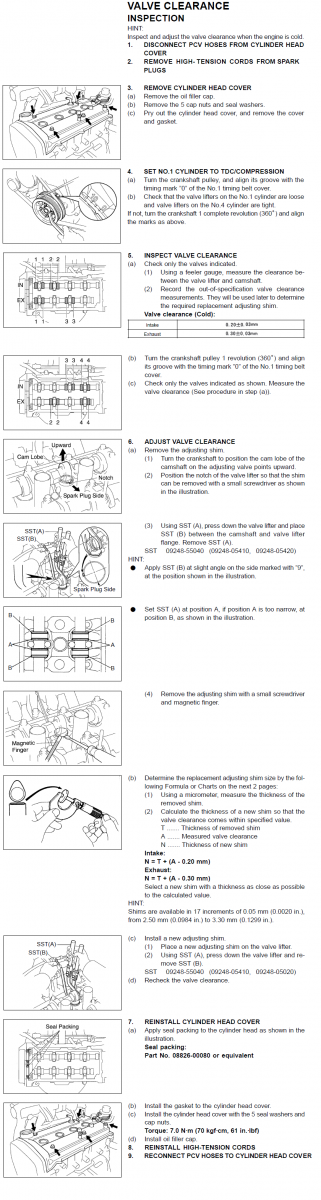

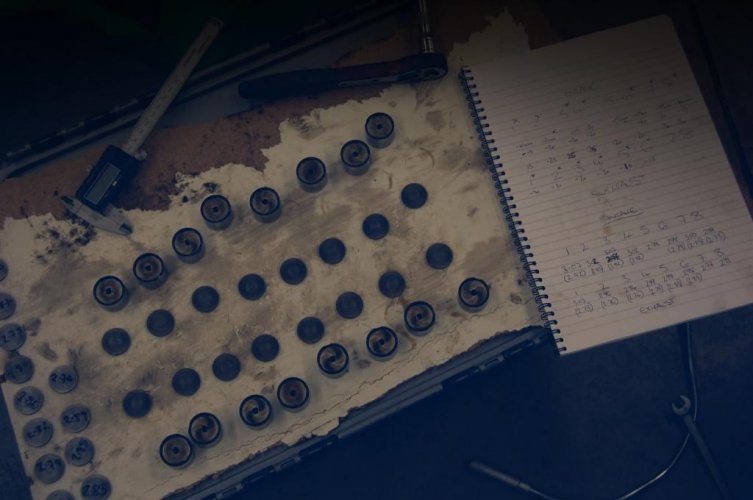

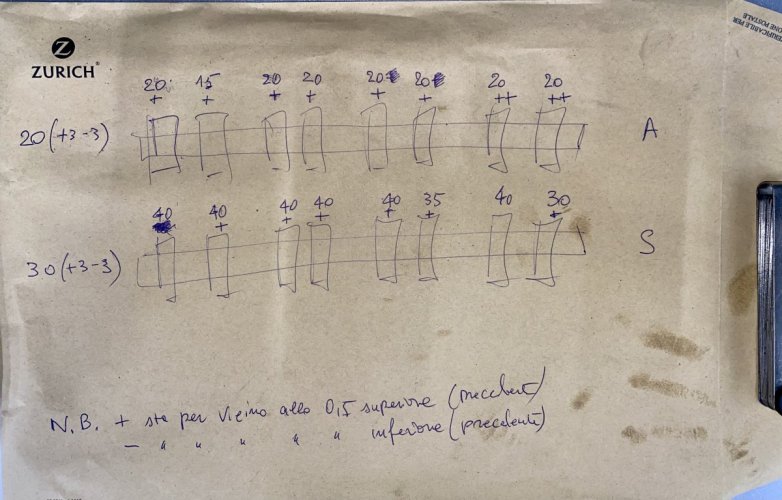

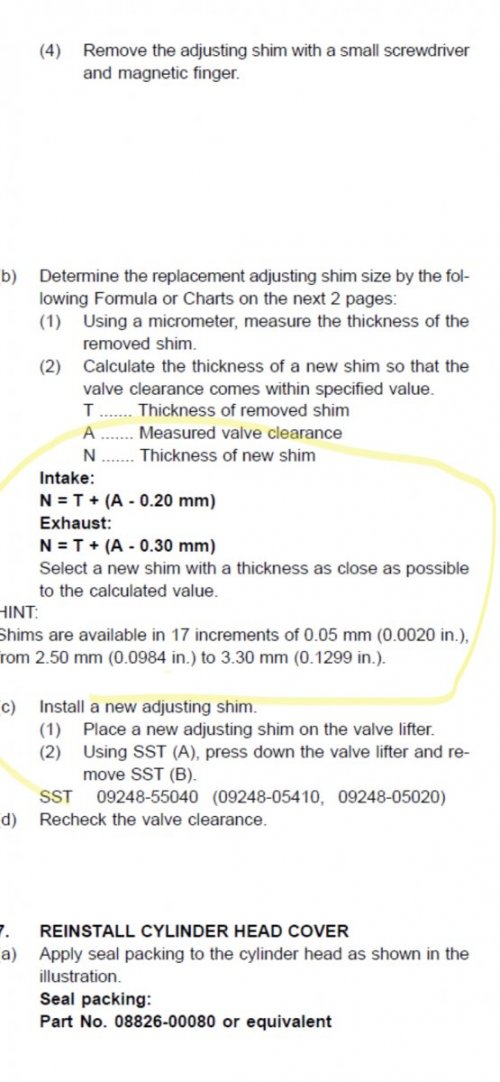

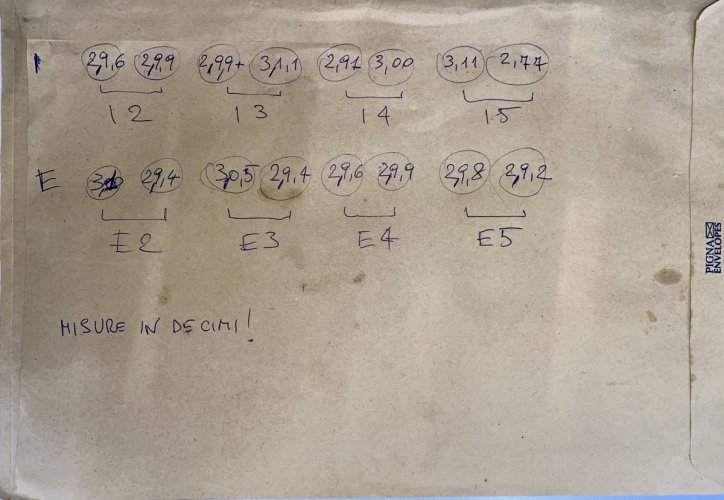

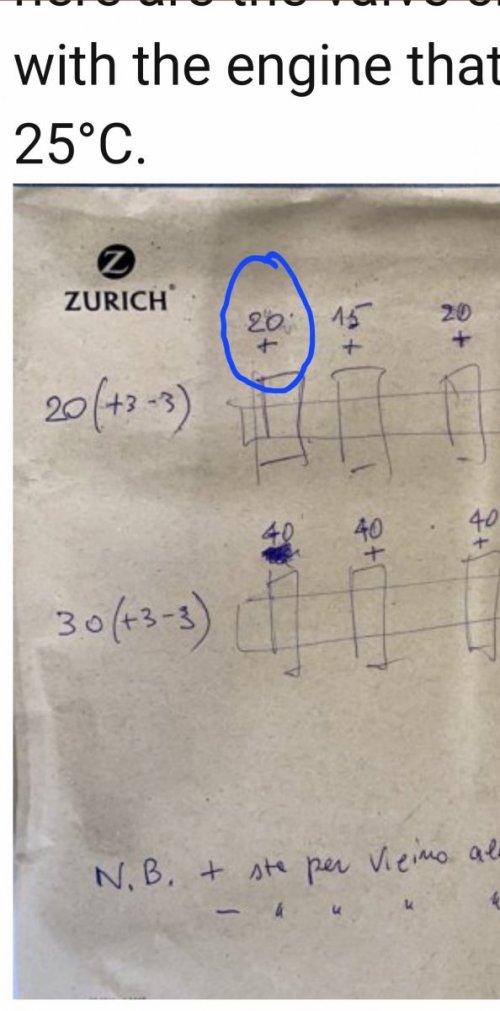

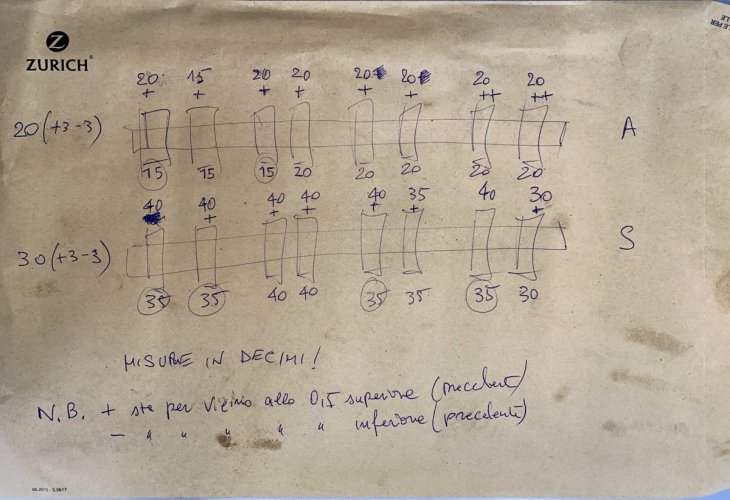

After the valves are refitted it's recommended to check the valve clearances. You will need the cam cover off and a set of feeler gauges. The valves aren't adjusted, the thickness of the valve buckets are instead. If the clearances are out of spec you might need different shims. Worry about that if it happens. Process will be in the manual, I think @JamesG_GlanzaV has an english version that I don't have. If one valve was sticking open you would be getting a misfire though.

The MAP sensor filter basically contains a fine mesh to catch oil vapour or gunge. A blast of carb cleaner should clear any blockages but you could remove it completely to see if that helps for testing.

A tuner should have access to a wideband so let him see if he can figure that side of things out.