Frankieflowers

Member +

Finally a good news!

The workshop didn’t react positivity to the idea that the engine would be better with the correct shim measures. Explaining him the symptoms the engine had made him react weirdly and told me he would have to work on it himself..i would never let that happen. I told him that if the valves would’t seal as they supposed to it was because of the rectification.

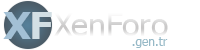

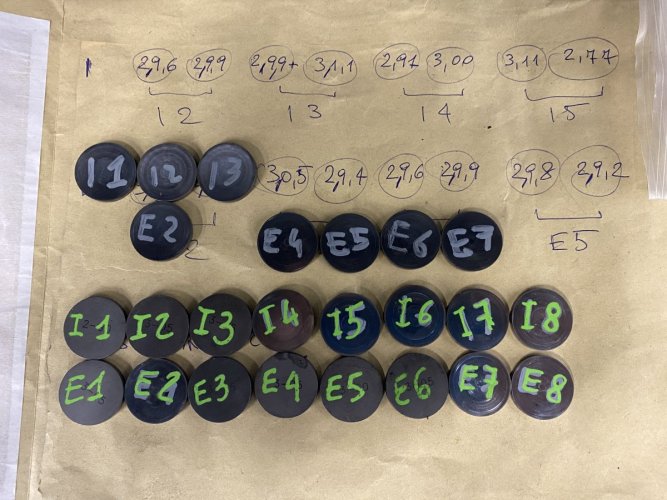

So I spoke to other professional mechanics and a different workshop that was very nice to explain that everyone makes mistakes but the good guys admit it. I went to the workshop who did the job and the owner gave me the shims I needed and I went home. I spoke about it with my partner and we decided that the best idea was to try the shims on and see what would’ve happened. If the car wouldn’t react right then we would’ve had to get the cylinder head off again to bring it to another workshop. The old-school technique is to use abrasive paste that to seal the valves perfectly. The workshop used a machinery to do it and apparently the big guys say that they don’t do their job well and the engines blow especially when they are u

Supercharged race cars. So we ended up putting the shims on and the engine seems to work again and I am very happy about it. It does a little more noise because of the new shims that apparently aren’t smooth as the original ones. Probably they will smooth out working. Today we will try the cylinder compression test again to see if something changed and we gained back the correct compression. I will update you as soon as we do the test.

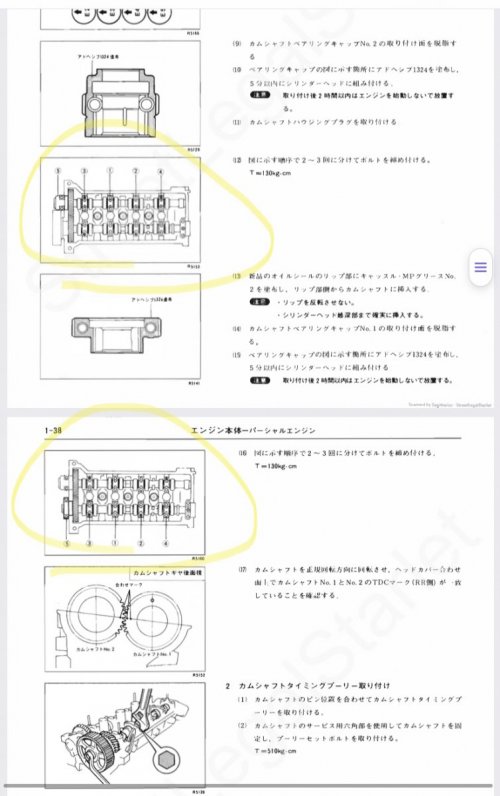

This engine compression rate is 8.2 to 1. If I lower the cylinder head about 2 1/10 mm I should be able with the formula to understand the new compression ratio. Otherwise I have to buy the pipe machine and do it with liquid. A race car mechanic told us that you cannot go above 0.5 from your original compression rate otherwise you will have to smooth out the angle created between the cylinder head and the cylinders. That angle would create high temperatures that will blow your engine sooner or later.

The workshop didn’t react positivity to the idea that the engine would be better with the correct shim measures. Explaining him the symptoms the engine had made him react weirdly and told me he would have to work on it himself..i would never let that happen. I told him that if the valves would’t seal as they supposed to it was because of the rectification.

So I spoke to other professional mechanics and a different workshop that was very nice to explain that everyone makes mistakes but the good guys admit it. I went to the workshop who did the job and the owner gave me the shims I needed and I went home. I spoke about it with my partner and we decided that the best idea was to try the shims on and see what would’ve happened. If the car wouldn’t react right then we would’ve had to get the cylinder head off again to bring it to another workshop. The old-school technique is to use abrasive paste that to seal the valves perfectly. The workshop used a machinery to do it and apparently the big guys say that they don’t do their job well and the engines blow especially when they are u

Supercharged race cars. So we ended up putting the shims on and the engine seems to work again and I am very happy about it. It does a little more noise because of the new shims that apparently aren’t smooth as the original ones. Probably they will smooth out working. Today we will try the cylinder compression test again to see if something changed and we gained back the correct compression. I will update you as soon as we do the test.

This engine compression rate is 8.2 to 1. If I lower the cylinder head about 2 1/10 mm I should be able with the formula to understand the new compression ratio. Otherwise I have to buy the pipe machine and do it with liquid. A race car mechanic told us that you cannot go above 0.5 from your original compression rate otherwise you will have to smooth out the angle created between the cylinder head and the cylinders. That angle would create high temperatures that will blow your engine sooner or later.