You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

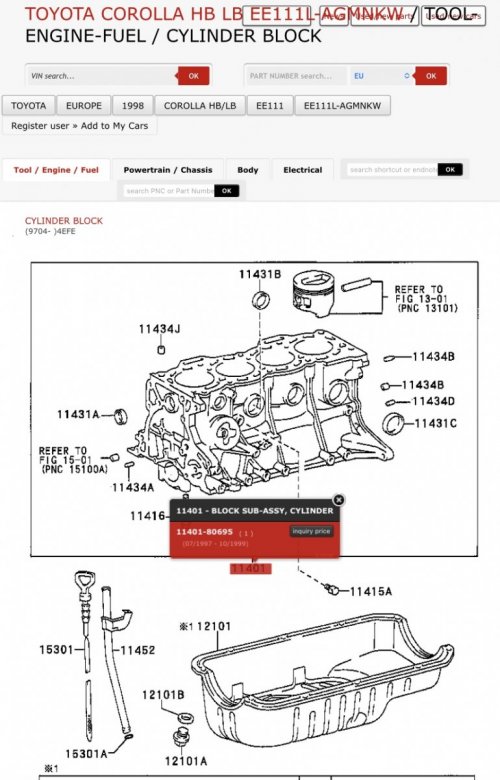

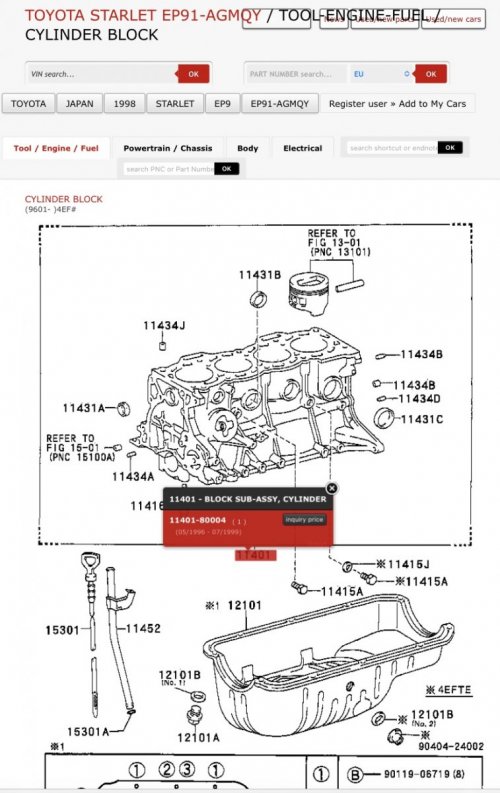

4EFE vs 4EFTE engine block differences for forged engine build.

- Thread starter Frankieflowers

- Start date

Jay

Admin

What part numbers are you getting for the two cylinder heads?

I definitely had differences between the E11 Corolla head and the turbo models, nothing major but enough to make the part numbers different.

Valves are the same, the valve springs make the difference (stronger).

With regards to the block, rebuild it with forged pistons and rods to suit the bores and crank. The bearings will be measured and specced by your engineering shop. Basically you are just strengthening it to deal with boost. Replace all the seals and the oil pump whilst it is apart just like a regular overhaul.

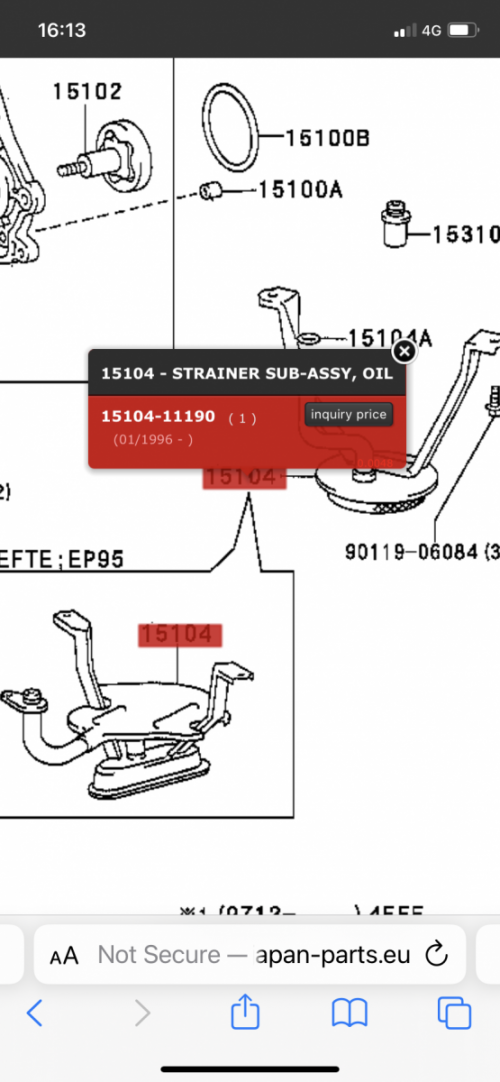

Sump on the turbo models has a return port on the front, otherwise both 4EFE and 4EFTE use the same sump/pick up/pumps as each other. One thing to be aware of is that there were variations depending on model year/region so be careful to replace like for like.

I definitely had differences between the E11 Corolla head and the turbo models, nothing major but enough to make the part numbers different.

Valves are the same, the valve springs make the difference (stronger).

With regards to the block, rebuild it with forged pistons and rods to suit the bores and crank. The bearings will be measured and specced by your engineering shop. Basically you are just strengthening it to deal with boost. Replace all the seals and the oil pump whilst it is apart just like a regular overhaul.

Sump on the turbo models has a return port on the front, otherwise both 4EFE and 4EFTE use the same sump/pick up/pumps as each other. One thing to be aware of is that there were variations depending on model year/region so be careful to replace like for like.

Jay

Admin

i checked all the possible different parts. I need to find a 4efte water output to have 2 water feeds for the turbo. Or maybe I can use an adaptor tirbo feed kot?

Can ypu help me with that?

Missed this bit. You can run the turbo without coolant lines (more common on the TD04 setups) but a CT9 will really prefer some help on higher boost applications. Ideally find a used turbo thermostat housing to swap across.

Frankieflowers

Member +

I still haven’t found it, but worst case scenario, I can swap it from my turbo engine. Maybe someone on the Forum has an extra one?Missed this bit. You can run the turbo without coolant lines (more common on the TD04 setups) but a CT9 will really prefer some help on higher boost applications. Ideally find a used turbo thermostat housing to swap across.

Frankieflowers

Member +

Do you suggest boring the cylinders to 74.5 mm or keep them OEM?What part numbers are you getting for the two cylinder heads?

I definitely had differences between the E11 Corolla head and the turbo models, nothing major but enough to make the part numbers different.

Valves are the same, the valve springs make the difference (stronger).

With regards to the block, rebuild it with forged pistons and rods to suit the bores and crank. The bearings will be measured and specced by your engineering shop. Basically you are just strengthening it to deal with boost. Replace all the seals and the oil pump whilst it is apart just like a regular overhaul.

Sump on the turbo models has a return port on the front, otherwise both 4EFE and 4EFTE use the same sump/pick up/pumps as each other. One thing to be aware of is that there were variations depending on model year/region so be careful to replace like for like.

Frankieflowers

Member +

Yes. I will install a new water pump and oil pump. I already bought the overhaul OEM kit to replace all gaskets. I need to buy the correct oil sump return pipe to fit the 4efe sump Which aftermarket adapter ahould I buy? I’ll get it welded in the sump together with the head cover AN10 adapters for the upgraded oil breathers.Basically you are just strengthening it to deal with boost. Replace all the seals and the oil pump whilst it is apart just like a regular overhaul

Frankieflowers

Member +

Ok with the hose but ai have to make the hole and fit a aluminium pipe in the sump as the 4efe doesn’t have it. I need to know which size AN I should buy. It would be like this one in the picture. Probably a AN12?The return pipe from turbo to sump is just a 90⁰ oil resistant silicone bend. You would cut to suit during installation.

Frankieflowers

Member +

@JayDo you have pictures of the distributor holes in the 4efe compared to the 4efte? I need tc be ready to do the fix as my 4efe has coil. View attachment 9901

here’s my 4efe coil block side

Frankieflowers

Member +

Hey guys. I need a little help to make sure ai don’t make mistakes during the process.

I need to buy Wossner pistons. Probably 74 mm as the cylinders should be ok. I just bought Maxpeedrods rods for the 4efe/4efte. Found a good deal in Germany so avoided customs.

Now I need to buy uprated valve springs (probably from TD) and bearings and low end bearings. There should be a ACL full set that covers everything.

About the head gasket. There are different measures and I don’t know why. Probably for the skimming process, but usually skimming doesn’t go lower than 2/10 mm. What do you suggest in case I do a 1/10 mm skimming on the head and a 1/10 mm on the engine block? I need a piece of advice here.

Last thing I don’t understand is the ACL head bolts and studs kit. What should ai buy?

I know I eill have to get bothe head and vlock adapted to M10x1.25 studs in the engine block and 10.5 mm drilled in the head.

Anyone can confirm?

thanks!

I need to buy Wossner pistons. Probably 74 mm as the cylinders should be ok. I just bought Maxpeedrods rods for the 4efe/4efte. Found a good deal in Germany so avoided customs.

Now I need to buy uprated valve springs (probably from TD) and bearings and low end bearings. There should be a ACL full set that covers everything.

About the head gasket. There are different measures and I don’t know why. Probably for the skimming process, but usually skimming doesn’t go lower than 2/10 mm. What do you suggest in case I do a 1/10 mm skimming on the head and a 1/10 mm on the engine block? I need a piece of advice here.

Last thing I don’t understand is the ACL head bolts and studs kit. What should ai buy?

I know I eill have to get bothe head and vlock adapted to M10x1.25 studs in the engine block and 10.5 mm drilled in the head.

Anyone can confirm?

thanks!

daniel_g

Member +

You need to speak to the engine machinist who will be building your engine. They will inspect the block, crank and head then advise which exact size components you will need.

I would suggest only buy 74mm pistons after the block has been properly inspected. Or go 74.5mm and have it rebored.

The ACL bearing kit can be bought as a complete set, in standard size if the crank is ok.

Headgasket thickness relates to compression ratio. Thinner the gasket then higher the compression ratio will be. So depends on what Wossnor pistons you buy and how much boost you want to run.

ARP headstuds do require block and head machine work.

ARP main studs, you ideally need the crank to be line bored.

Again, an engine machinist is the best person to speak to.

I would suggest only buy 74mm pistons after the block has been properly inspected. Or go 74.5mm and have it rebored.

The ACL bearing kit can be bought as a complete set, in standard size if the crank is ok.

Headgasket thickness relates to compression ratio. Thinner the gasket then higher the compression ratio will be. So depends on what Wossnor pistons you buy and how much boost you want to run.

ARP headstuds do require block and head machine work.

ARP main studs, you ideally need the crank to be line bored.

Again, an engine machinist is the best person to speak to.

Frankieflowers

Member +

Thank you for the info. I had a chat with Sean Hurley amd he confirms that the engine block has to be machined to fit the Maxpeedingrods I bought.You need to speak to the engine machinist who will be building your engine. They will inspect the block, crank and head then advise which exact size components you will need.

I would suggest only buy 74mm pistons after the block has been properly inspected. Or go 74.5mm and have it rebored.

The ACL bearing kit can be bought as a complete set, in standard size if the crank is ok.

Headgasket thickness relates to compression ratio. Thinner the gasket then higher the compression ratio will be. So depends on what Wossnor pistons you buy and how much boost you want to run.

ARP headstuds do require block and head machine work.

ARP main studs, you ideally need the crank to be line bored.

Again, an engine machinist is the best person to speak to.

I also bought 200-8745 ARP washers for head studs or bolts, as the ones in the ARP kit are too big.

Sean told me as you just confirmed that to use main studs the crank will have to be machined. Do you suggest doing it or should I keep the crank OEM and machine only the hard and block to for head studs? The engine has to be strong to hold 300+ HP. I don’t need to spend all this money to run 200 hp.

I also read some comments about uprating the valve springs. I would buy the Performance Springs. Is it a good idea?

Let me know ehat you think. Thanks!

daniel_g

Member +

Many people have run over 300bhp using ARP main bolts and not studs.

I think it is worthwhile going for the studs.

As for the valve springs, I went for this kit, springs and titanium retainers.

https://raceeng.com/race-engineering-springs-retainers-toyota-4e-fte-5efe-kit/

Not had them fitted yet as still collecting more parts so I can't comment on the performance.

I think it is worthwhile going for the studs.

As for the valve springs, I went for this kit, springs and titanium retainers.

https://raceeng.com/race-engineering-springs-retainers-toyota-4e-fte-5efe-kit/

Not had them fitted yet as still collecting more parts so I can't comment on the performance.

Frankieflowers

Member +

Thank you for the info! I am speaking with TD as well. They have a valve uprated valve spring kit they have developed. Don’t know the quality but should be ok? It costs a bit less. I should buy it together with the remaining parts I need which qre:Many people have run over 300bhp using ARP main bolts and not studs.

I think it is worthwhile going for the studs.

As for the valve springs, I went for this kit, springs and titanium retainers.

https://raceeng.com/race-engineering-springs-retainers-toyota-4e-fte-5efe-kit/

Not had them fitted yet as still collecting more parts so I can't comment on the performance.

Wossner pistons

ACL full bearing kit

Cometic or Athena 1.4 head gasket

ARP Headstuds

ARP Mainstuds

OE water pump (will probably buy the OEM pump from Toyota

I already bought:

OEM oil pump

ACL head washer kit

Maxpeedingrods

4efte camshafts

Regarding the machine shop work.

Probably no cylinder boring.

Head skim 0.2 mm

The areas where the bolts will go will need to be relieved such as the block to leave space to the racing rods.

The head will have to be drilled 10.5 mm for the studs that will have to be shortened as well.

The block will have to be drilled and tapped for the M10 studs.

Frankieflowers

Member +

Frankieflowers

Member +

Here are the clean (apparently) 4efte camshafts I just bought from Japan, compared to the (darker) 4efe camshafts I removed from my Corolla E11 4efe.

i measured the olives and the are exactly the same. Do you recognize them as 4efte camshafts? The only difference is the number on the inlet cams.

let me know what you think. Thanks!

i measured the olives and the are exactly the same. Do you recognize them as 4efte camshafts? The only difference is the number on the inlet cams.

let me know what you think. Thanks!

Frankieflowers

Member +

I found a pipe that should work. When you have a chance can you please send me a picture of how it looks from the inside? There must be a flat bolt that holds it in place.Quick measurement of a glanza sump for comparison.

Frankieflowers

Member +

Hey guys! Anyone commenting about the cams?

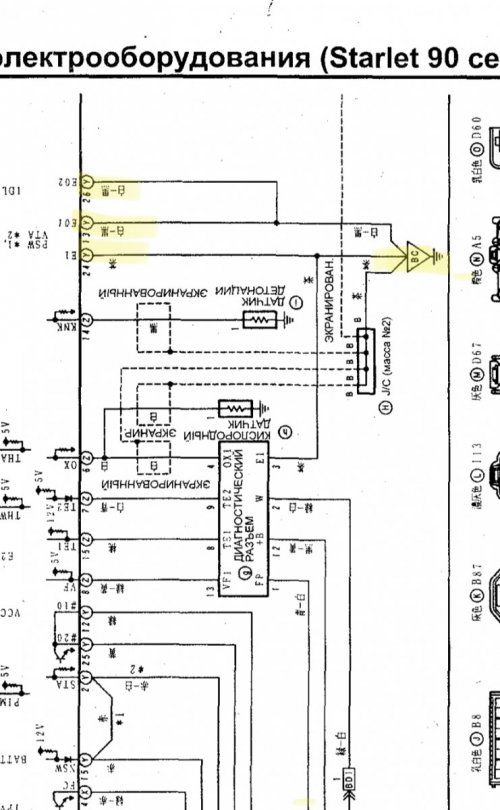

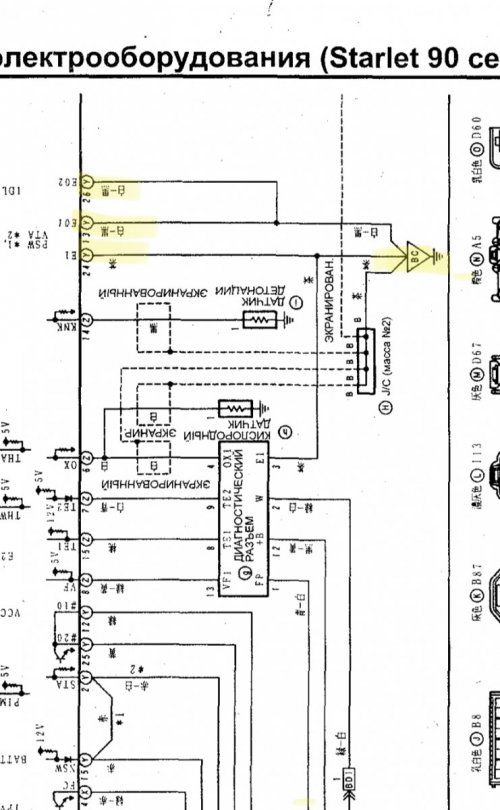

i have a question. Where does the 3 computer ground wires go from the ECU? I have some ground issues and need tocfigure it out. I hope that you can help. @Jay

My wiring manual is in Russian. Need some help from whom has the Snglish version

i found this page with the 3 computer ground pinouts. They go to BC ground. Ehat’s the difference between BC and DH ground?

UPDATE.

I managed to find the ground route that goes from ECU connector one to the inlet. All 3 E1, E01 and E02 are where should be doing through Junction J15.

The DET3 is causing the engine check light to turn on on boost. It must be a voltage or ground issue that the ECU detects as a anomalie. I want to solve this but I ran out of ideas.

The last thing I will try is to connect to computer ground the free analog inputs. It is advised in the manual.

Should I wire the free analog inputs to the E01, E02 ground and leave alone E1 as already in use in the DET 3 connector with the 12V from the EXU loom?

i have a question. Where does the 3 computer ground wires go from the ECU? I have some ground issues and need tocfigure it out. I hope that you can help. @Jay

My wiring manual is in Russian. Need some help from whom has the Snglish version

i found this page with the 3 computer ground pinouts. They go to BC ground. Ehat’s the difference between BC and DH ground?

UPDATE.

I managed to find the ground route that goes from ECU connector one to the inlet. All 3 E1, E01 and E02 are where should be doing through Junction J15.

The DET3 is causing the engine check light to turn on on boost. It must be a voltage or ground issue that the ECU detects as a anomalie. I want to solve this but I ran out of ideas.

The last thing I will try is to connect to computer ground the free analog inputs. It is advised in the manual.

Should I wire the free analog inputs to the E01, E02 ground and leave alone E1 as already in use in the DET 3 connector with the 12V from the EXU loom?

Last edited: