Frankieflowers

Member +

Those Australian guys have a great experience on these engines. They had the chance to make many mistakes and experiments on them.The easiest way to do the oil feed is by using the FTE oil filter housing. Some exhaust manifolds won't actually fit unless the oil filter is in this position, as opposed to directly on the block the N/a way, so something to watch out for.

Again regarding the ARP studs, mine were not cut. My machinist must have just drilled down further.

I've seen that video before - that is a good channel to watch for information.

regarding the oil field there are two options besides the traditional FTE oil feed one is a short filter. The Australian guys use it. The other is a oil filter relocation kit. You connect a 45* feed out and put the oil filter on the chassis maybe underneath the AC lines.

it’s a solution I am considering as my turbo exit runs right in front of the oil filter and I want it in another location. I’ll see about that when the time is right.

Drilling further might weaken the block but it’s an option.

It’s good that se can exchange info while we proceed.

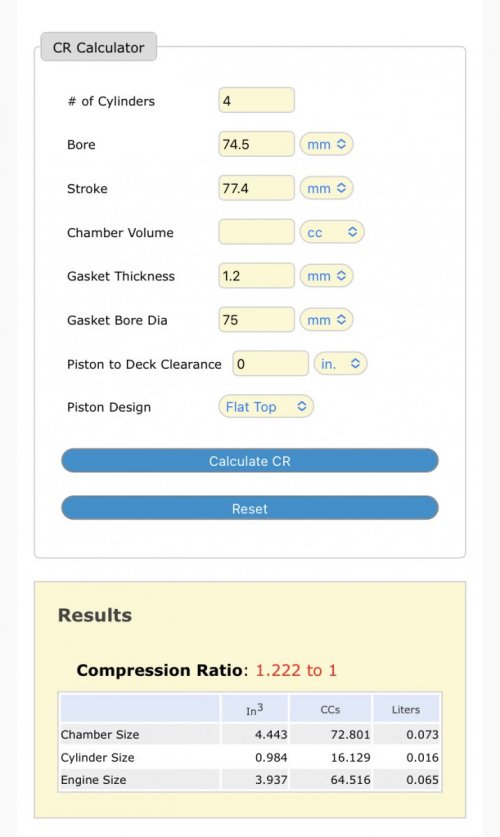

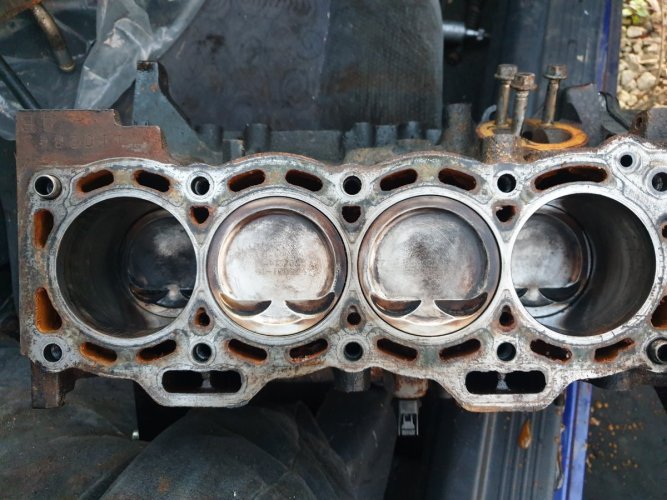

I bought almost everytging I need for the job. I’ll order bearings, studs and bolts in December. This months I’ll get the valves out of the head and take it to machine shop to get washed with the engine block. I’ll bring cams and crank shaft. I’ll not give them head internals as I want to build the head myself.It is very expensive so I prefer to save budget for the Wossner pistons. I’ll obviosly buy the pistons and head gasket after the machine shop will tell me if it is good or if it needs to be shimmed.